At present, Printed circuit boards (PCBs) have become an inherent part of many electronic devices. At the onset, PCBs were comparatively simple, single or double-layered, and were used for very specific and limited purposes. However, as technology evolved, the need for smart and sophisticated electronic devices increased due to which the developers braced the task of producing more complex and multi-functioning PCBs. This led to the development of multi-layered PCBs that are much more diverse, flexible in design, and can carry out several operations simultaneously. The demand for these multilayer PCBs has increased manifold in the past few years because of their functional versatility.

In the last few decades, the demand for small intricate devices in both domestic and industrial devices increased significantly, which warranted a need for PCBs that are smaller in size and can fit into any shape. The manufacturers have done a remarkable job in developing multilayer PCBs that are smaller in size, lighter in weight, more durable and flexible, and can serve the purpose of both rigid and flexible PCBs. Because of these versatile functions, multilayer PCBs are used so widely in almost all the modern and complex electronic devices ranging from military equipment, medical devices, computer electronics, telecommunication, automotive, aerospace, and many more. It would not be wrong to say that multilayer PCBs have brought a revolution in the field of electronics and have made our lives better.

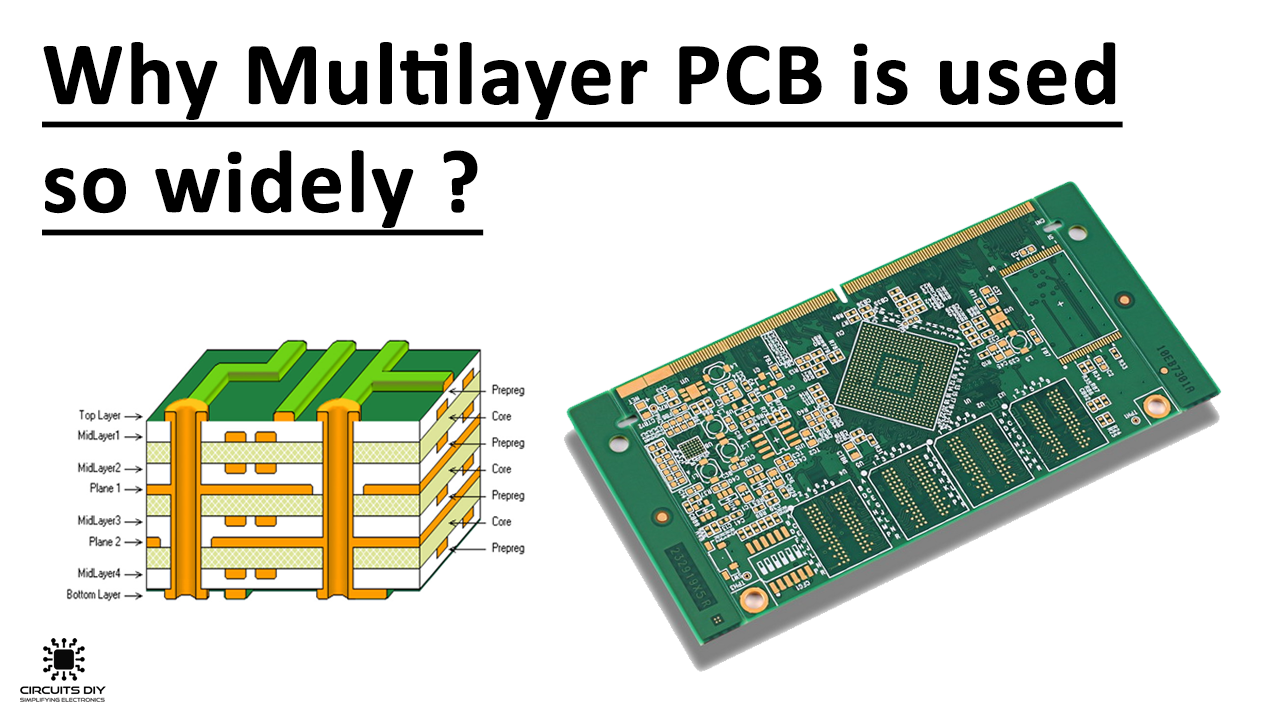

What is a Multi-Layer PCB?

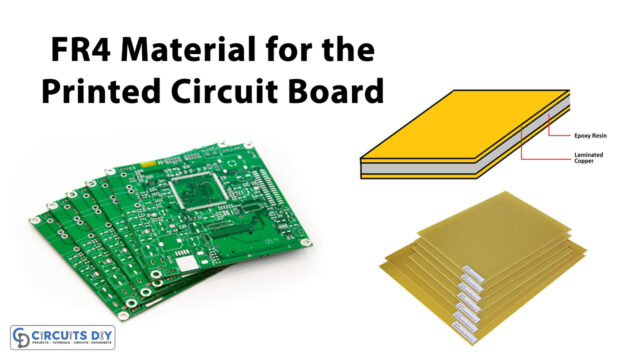

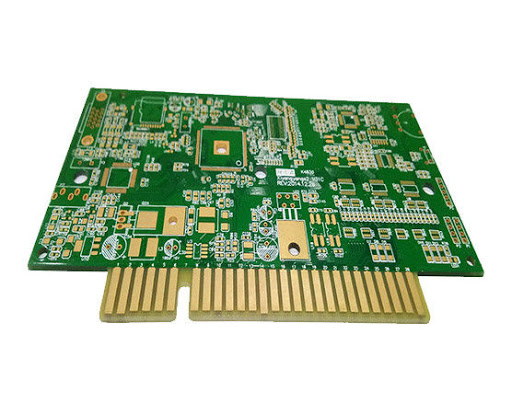

A multilayer PCB is made by at least three layers of conductive layers, generally of copper, stacked over one another. An insulating layer is present between the layers to prevent the melting of layers due to excessive heat generated during its operation. These conductive layers are stacked at the center of the board. This arrangement of layers increases the surface area for wiring connections and also allows it to be more densely packed and as a result, it covers much less space. The number of layers in a multilayer PCB can range from 3 to 12. However, as thick as 50-layer PCBs have also been manufactured. The number of layers depends upon the needs and requirements of the users.

Why choose PCBONLINE multilayer PCB ?

PCBOnline is a multilayer PCB manufacturer with 15 years of experience in china. With rich professional manufacturing experience in multilayer PCB technology.

Reasons Highlighting Widespread Use of Multi-Layer PCB

As technology improved over the years, the electronic industry has gone under tremendous changes. The demand for small, lightweight, and high-density electronic appliances is increasing day by day that warrant more complex PCBs. Similarly, single- and double-layer PCBs showed issues like excessive noise, electromagnetic interference, capacitance, hence, the need and demand for sophisticated designs increased. So, multilayer PCBs were developed to address all the issues present in simple PCBs.

Multilayer PCBs are used worldwide because they offer a myriad of advantages to simple PCBs. Although they are a bit expensive and require due considerations in their design but they offer design versatility, high reliability and durability, strong resistance to temperature, pressure, and other tough industrial conditions that cannot be achieved by using a single- or double-layer PCB. These benefits are explained in detail in the below paragraphs.

Benefits of Multilayer PCBs

Multilayer PCBs are used in all modern electronic devices because they serve a plethora of advantages. Some of the significant benefits of multilayer PCBs are:

Diversifies Design Functionality

Due to the flexibility in their design, the functional capabilities have increased significantly. They can serve many operations simultaneously. You can easily fit more electronic components and wiring connections because of many layers. Similarly, the introduction of controlled impedance attributes, EMI shielding, smaller size, and better design, multilayer PCBs provide a wide array of diverse functions.

Can be Made Rigid, Flexible, or Both

One of the foremost advantages of multilayer PCBs is that they can be manufactured either flexible or rigid or both (Rigid-Flex PCB) depending upon the requirements. But as the number of layers is increased, it becomes more rigid and less flexible.

Smaller in Size

Multilayer PCBs come in small sizes as compared to a single or a double-layer PCBs as multiple layers can be stacked over each other to reduce size. It increased their functional capacity and helps them to fit into smaller, more complex devices easily and perform more complicated tasks at relatively higher speeds. Also, small size increased the mobility of electronic devices that is an inherent feature of modern electronics.

Lighter in Weight

As multiple layers are connected over one another, their footprint decreases and it not only reduces their size but also weight. This lightweight allows such PCBs to be used in many electronic appliances as the modern demand is continuously towards lighter and smaller electronic devices. Appliances like laptops, mobiles, tablets, etc. are evolving smaller and lighter because of multilayer PCBs.

Premium Quality

As the need for high-precision electronic devices increased, so did the requirement of high-quality PCBs. Multilayer PCBs serve this purpose and are long-lasting and more reliable because of better planning and working in their designing process. That is why they offer high quality and better workability than any single- or double-layer PCB.

Enhanced Durability

Because of light-weight and smaller size, multilayer PCBs tend to be more durable in their nature. Not only they easily withstand their weight but they also provide more mechanical support to the circuits they are connected with. Similarly, they are more resistant to temperature and pressure produced during working. On top of these factors, unlike simple PCBs, they can withstand tough industrial conditions and that’s why all industrial electronic appliances employ multilayer PCBs.

Provide Single Connection Point

Since multiple layers are connected, so it provides a single connection source, unlike single layer PCBs where each layer requires a separate connection. In this number of connections is reduced significantly and it also decreases the number of potential wiring failure points. Moreover, less connection leads to reduced weight and size which is a prerequisite for modern appliances. Hence, these PCBs are always preferred for all the smart and sophisticated modern electronic devices.

Increased Functional Capacity

The electronic components on the surface of multilayer PCBs are densely packed and give the configuration of a single PCB. It allows them to be more efficient in their conductivity, less wire breaking points, perform diverse functions, at remarkably high speeds.

Due to these remarkable benefits, multilayer PCBs are used worldwide in all the latest electronic devices ranging from simple domestic appliances to commercial high-functioning devices as the propensity of people for small and lightweight devices is increasing rapidly.

Applications of Multilayer PCBs

As mentioned earlier, multilayer PCBs have a high initial cost and require sufficient time in manufacturing, however, their benefits easily outweigh these costs and they are now considered as the cost-effective PCBs for high-density and sophisticated electronics. No wonder, customers are willing to pay more for these PCBs and their acceptability is continuously increasing. More and more industries are turning towards using multilayer PCBs in their electronic products. From military and medical devices to complex aerospace and automobile instrumentation, these PCBs have become an innate part of modern electronics.

Closing Remarks

In short, multilayer PCBs offer considerable advantages over regular PCBs, and though their initial cost is higher, but their performance in terms of functionality, and reliability easily covers up their price. That is why almost all the modern electronic applications employ these boards.

Want to learn more about multi-layer PCB? Click here to see more.