Introduction to PCB

A printed circuit board is an electronic circuit board that is used to connect different electronic components. Before PCB was invented, the circuit designer and professionals used the complicated method of point-to-point wiring, which was not effective and efficient. To get rid of that end-to-end wiring technique, Australian engineer Paul Eisler invented the PCB Board for the first time. After working on PCB designers thought to revolutionize the PCB, it got many productive ideas. And now PCB is evolving and innovating day by day.

PCBGoGo commits to meet the needs of its customers from different industries in terms of quality, delivery, cost-effectiveness, and any other demanding requests. As one of the most experienced PCB manufacturers in China. They pride themselves to be your best business partners as well as good friends in every aspect of your PCB needs.

PCBs are consist of composite material, epoxy, and fiberglass. Initially, PCBs were developed through-hole technology, in which components were mounted to leads were inserted through the hole, and then soldered on the other side. Later in 1960, the surface mount technology gets introduced and became popular in 1990, instead of components inserted in a hole, now components have end caps that get soldered into PCB and components can place on both sides of the Printed circuit board, the size also got smaller. Surface mount technology has become an ideal choice for circuit designers.

Types of Printed Circuit Board And Their Uses

The different types of the Printed circuit board to design electronic devices and circuits are described below:

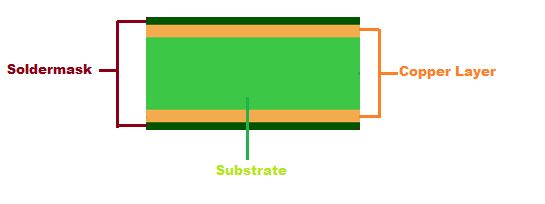

Single-layer PCB

The single layer is the most basic type of PCB which contains only one layer of the substrate material. The layer has thin copper material covered. It also has a protective mask.

Uses of Single-layer PCB

- Since they have a low cost they can be utilized in volume generating circuits

- For simple and small circuits like sensors, toys, single-layered is a preferable choice because it’s cheaper

Double-layer PCB

Double-sided PCBs contain two sides of the substrate material. Components can be mounted in any of the layers. This PCB board uses both the schemes, that are, through-hole and, the surface mounting technique.

Uses of Double-layer PCB

- It can allow using of more components or more circuits on one board

- They are used in making many devices like a power monitoring system, amplifiers, other test equipment, etc

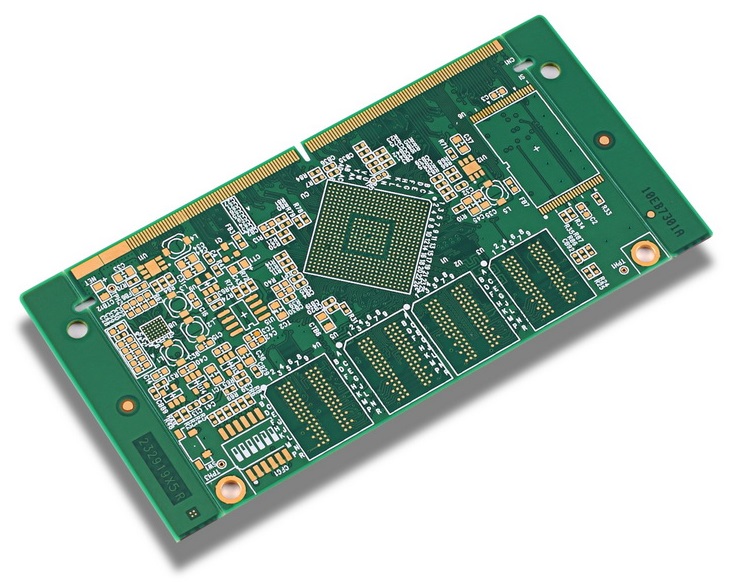

Multi-layer PCB

Multi-layer PCBs contain more than two layers of copper, they are portable and smaller in size. They have less weight and take less space

Uses of Multi-layer PCB

- They are more flexible to design circuits

- They can use in circuits for high speed, they increase conductivity

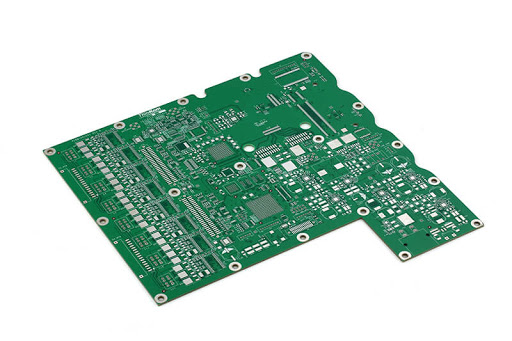

Rigid PCB

Rigid PCBs are those which are fabricated through solid material and cannot be bent.

Used of Rigid PCB

- Since these are compact, so, they are used for complex circuits

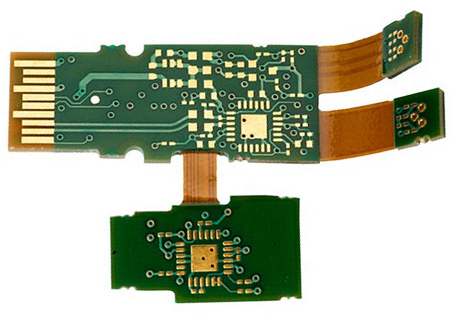

Flexible PCB

They have flexible substrate material. They can have single, double, and multilayers. They reduce the complexity and save more space because of the flexible base.

Uses of Flexible PCB

- They are used for tiny devices

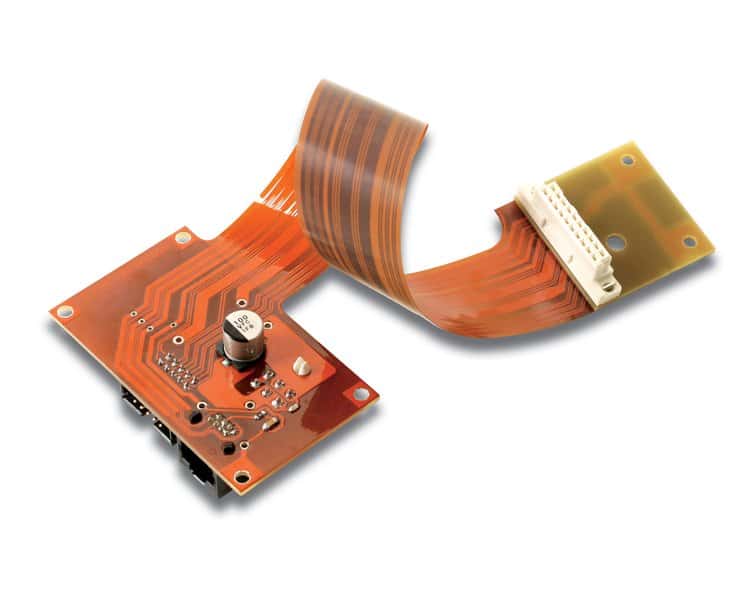

Rigid of Flex PCB

These are the combination of rigid and the flex PCB, they contain multiple flexible circuit layers connected to more than one board

Uses of Flexible Rigid PCB

- They are used in several military and medical applications

High Frequency PCB

These PCBs have a high-frequency range from 5000MHz to 2 GHz

Uses of High-frequency PCB

- It is used in a communication system application

Aluminum Backed PCB

This PCB is recognized to offer an outstanding level of rigidity and lower thermal expansion

Uses Of Aluminium Backed PCB

- They are used for high power application

- They are favorable for the applications having a high thermal expansion

Conclusion

PCBs are everywhere in the electronic industrial sector. They are used almost in every circuitry. They are more effective, beneficial, and more useful for electronic circuit designers.