PCB is an acronym for the Printed Circuit Board. A PCB is a thin board made of fiberglass or other laminate material. Conductive pathways are printed or etched onto the board which connects different components on the PCB, such as resistors, transistors, and integrated circuits.

JLCPCB is the foremost PCB prototype & manufacturing company in china, providing us with the best service we have ever experienced regarding (Quality, Price Service & Time).

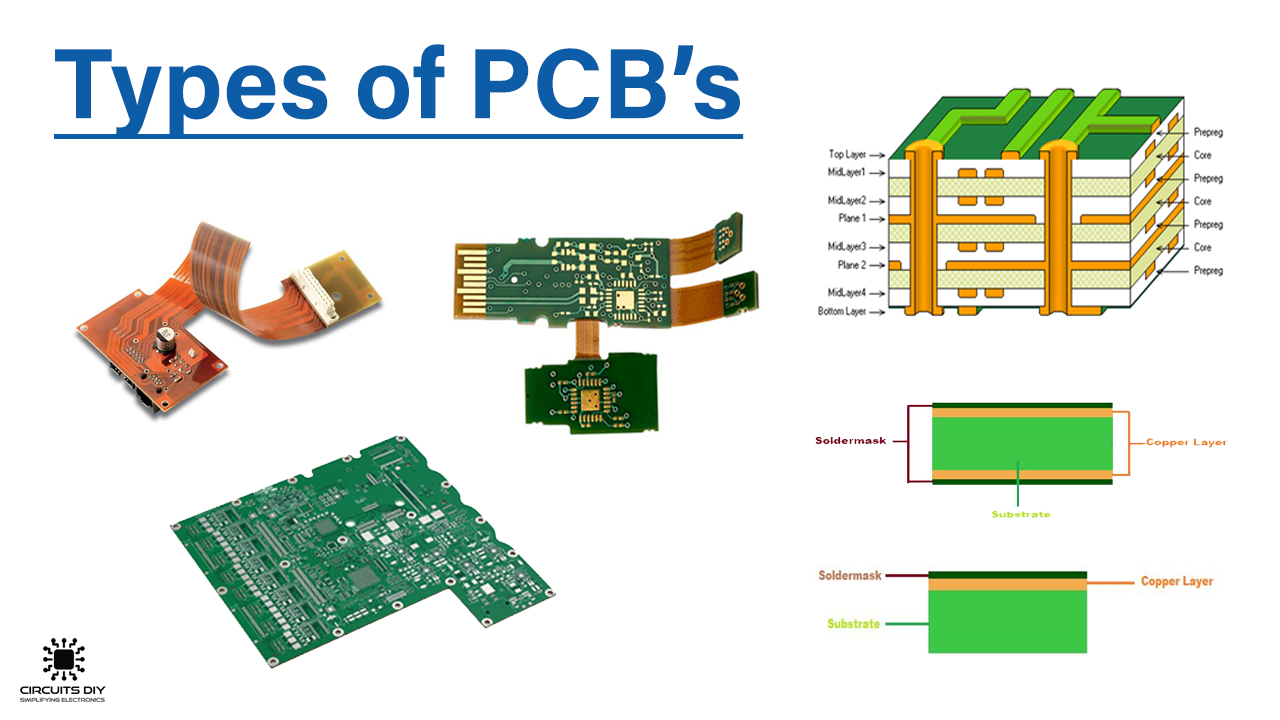

There are several types of PCB boards and each board has its own particular manufacturing specifications, material types, and usages. Out of these types of PCBs, we can choose the appropriate type of PCB according to our application. Given below is the list of PCBs available in the market:

- Single-layer PCB

- Double-layer PCB

- Multi-layer PCB

- Flexible PCB

- Rigid PCB

- Flex-rigid PCB

Single-layer PCB

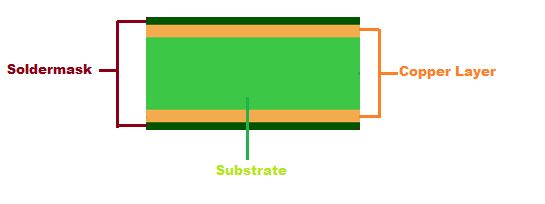

A single-layer is made of a single layer of base material and one single conductive (copper) layer. Single-layer means that the circuitry and the components are only on one side of the board. Single-layer PCBs are an ideal choice for beginners are mostly used in simple electronics projects. Although they are relatively cheap and easy to produce, there are limitations to what it can be used for. This type of PCB is commonly used for a variety of applications like calculators, cameras, radios, and power supplies.

Double-layer PCB

Double-layer PCB is similar to a single-layer PCB, except that they have conductive layers on both sides of the substrate. In double-layer PCB electronic components can be soldered on both sides. Conductive holes in the PCB allow the circuit on one side of the board to connect to the circuit on the other side. Double-layer PCBs are mostly used in applications that require complex circuits, such as industrial controls, power supplies, HVAC systems, and LED lighting.

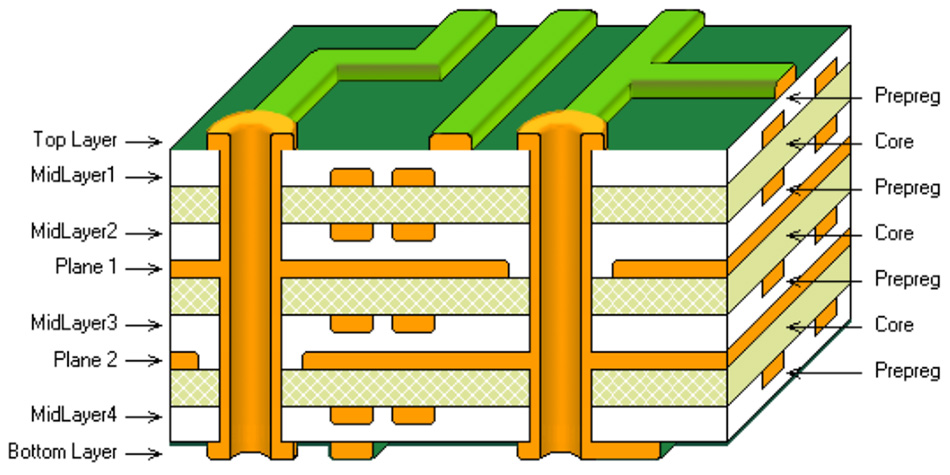

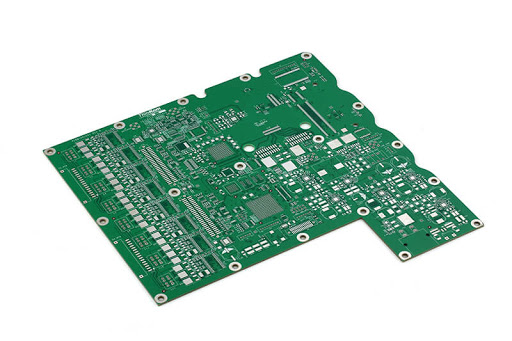

Multi-layer PCB

Multi-layer PCB has more than two layers which means that this type of PCB has at least three conductive layers of copper. All the layers can be interconnected with copper-plated holes. For securing the board, glue is sandwiched between the layer of insulation which ensures that the excess heat does not melt any component of the circuit. These types of PCBs are mostly used in advanced machineries such as medical equipment and servers.

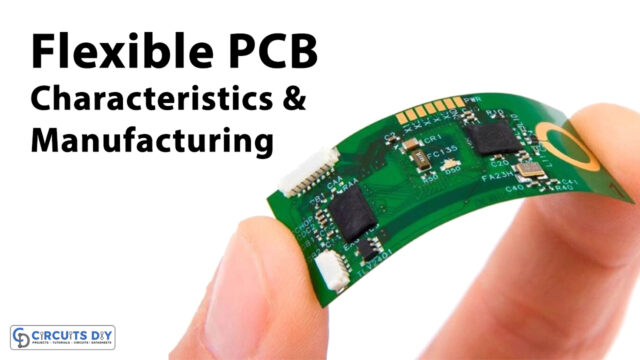

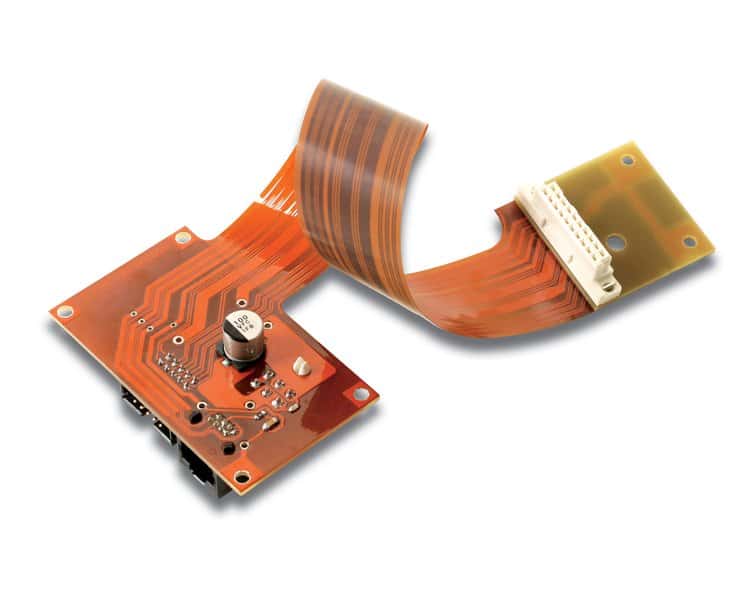

Flexible PCB

Flexible PCBs are printed circuit boards that are designed to be flexible and malleable. A Flex PCB can be a single-layer, double-layer, or multilayer PCB. The substrate of a flexible PCB is made of flexible plastic, polyimide, or a similar polymer. They tend to cost more for fabrication because they need to be printed on a flexible material. Flexible PCB is used in a wide range of applications including Flex solar cells, automotive industries, LEDs, and many more. JLCPCB creates both flexible and printed circuit boards for product manufacturers. Enjoy a consultation with one of their sales reps to find out if your product prototype design is best served by flexible or rigid circuit board types

Check JLCPCB flexible PCB manufacturing capabilities in the following table:

| Feature | Capability |

| Number of Layers | 1-8 layer |

| Build Time | 3-5days |

| Polyimide base material | Polyimide Flex |

| FPC Thickness | 0.08-0.4mm |

| Min Track/Spacing | >=0.06mm |

| Min Hole Size(diameter) | >=0.35mm |

| Coverlay(Flex Part) | Yellow Coverlay,White Coverlay,Black Coverlay |

| Silkscreen Color | White,Black |

| Surface Finish | Immersion gold,OSP,Immersion silver,Immersioni Tin |

| Finished Copper | 0.5-2oz |

Rigid PCB

Rigid PCBs are made of solid substrate material that prevents the board from twisting. It has different layer configurations like single-layer, double-layer, and multi-layer Rigid PCB. By making the board solid and immovable, the life of the components will increase as they will be less prone to environmental damages. These types of boards generate low electronic noise and minimize cross talk. A popular application of Rigid PCB is a computer motherboard.

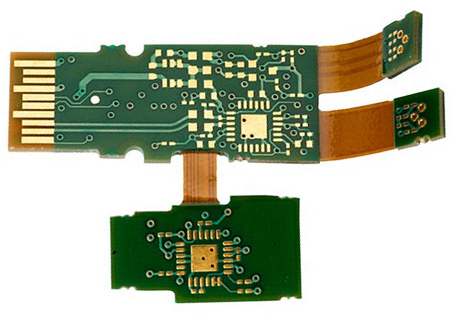

Flex-rigid PCB

Flex-rigid PCB is a combination of flexible PCB and rigid PCB. It consists of both rigid and flexible substrates that are laminated together to form a single circuit board. Flex-rigid boards tend to have fewer parts than flex or rigid board as the wiring for both boards can be combined into one board. Flex-rigid PCBs are mostly found in applications where space or weight are prime concerns for example Cell phones, Cameras, and Automobiles. JLCPCB also creates high-quality Rigid-Flex PCB’s.

Check JLCPCB Rigid-Flex PCB manufacturing capabilities in the following table:

| Feature | Capability |

| Material | Polyimide Flex+FR4 |

| Min. Track/Spacing | 4mil |

| Min. Hole Size | 0.15mm |

| Rigid-Flex Thickness | 0.4-3.2mm |

| FPC Thickness | 0.08-0.4mm |

| Solder Mask Color(Rigid Part) | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green |

| Covrelay (Flex Part) | Yellow Coverlay, WhiteCoverlay,Black Coverlay |

| Silkscreen | White, Black |

| Finish Cooper(Flex Part) | 0.5-2oz |

| Finish Cooper(Rigid Part) | 1-4oz |

| Via Process | Tenting Vias,Plugged Vias,Vias not covered |

| Additional Options | Half-Cut,Impedance Control |

| Build time | 10-20 days |

| Lead time | 2-3 days |