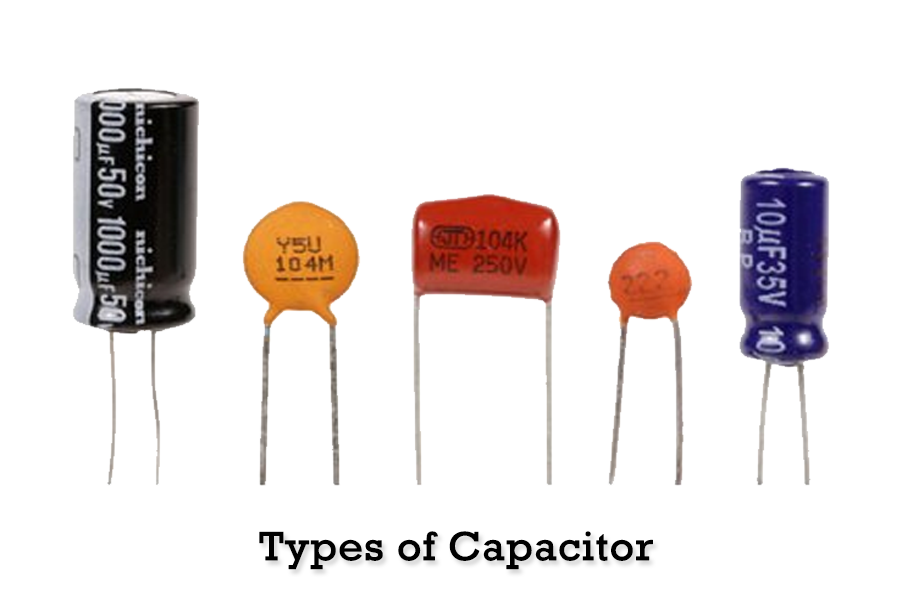

The capacitor is a vital component for any electronic circuit and devices, capacitors come up with different types based on different characteristics. As we all know, the capacitor is a component and stores electrical energy and often assumed as a small rechargeable battery.

Types of capacitor

Capacitors are classified based on different characteristics such as charging voltage, leakage rates, the capacity to bear charges, etc. These factors determine which type of capacitor fits best for which application.

Some of the different types of capacitors are the following.

- Electrolytic Capacitor

- Mica Capacitor

- Paper Capacitor

- Film Capacitor

- Non-Polarized Capacitor

- Ceramic Capacitor

Electrolytic Capacitor

Electrolytic capacitors are used for high capacitor values. At the anode, the thin metal film layer is used and at the cathode, a semi-liquid electrolytic solution is used. The dielectric plate consists of a thin layer of metal oxide and is developed electrochemically with a thickness of less than ten microns.

Applications:

- DC power supply circuit

- Used in applications where large capacitance is required.

Mica Capacitor

These capacitors are made by deposition of a thin layer of silver on a mica dielectric. Mica capacitors are of 2 types namely as a clamped capacitor and silver mica capacitor. The clamped capacitor is not used nowadays because of characteristics and compatibility issues, while silver mica capacitors are commonly used because of their stability.

Applications:

- Resonance circuits

- High-frequency filters

- High-voltage circuits

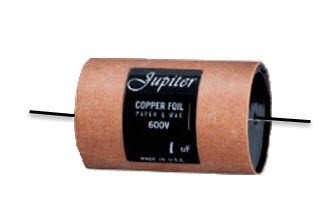

Paper Capacitor

This Capacitor is a fixed capacitor in which flat thin strips of metal foil usually aluminum is distanced by dielectric material paper. Paper capacitors range from capacitance value 1nF to 1uF mainly at power line frequency. Paper capacitors provide fixes capacitance

Applications:

- High Voltage & High Current Applications

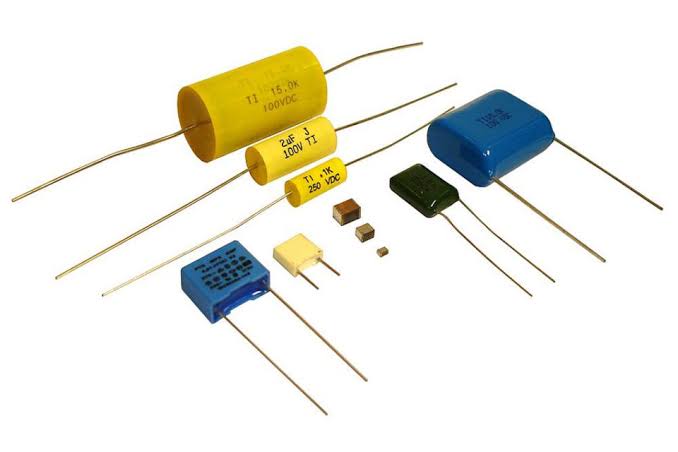

Film Capacitor

In film capacitors, plastic film is inserted to construct the dielectric and aluminum/zinc is also used to construct the electrodes of the capacitor. Film capacitors are also known as film dielectric capacitors with the special ability of low self-inductance and great stability.

Applications:

- A/D converters

- Motor run

- Filters.

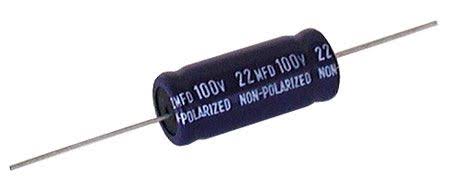

Non-Polarized Capacitors

Non-polarized capacitors are capacitors without any polarity. The two electrodes of non-polarized capacitors can be randomly put into the circuit, and will not leak, The figure shows the reference diagram of the non-polarized capacitor.

Applications:

- Coupling & decoupling

- Feedback

- Compensation

- Oscillation

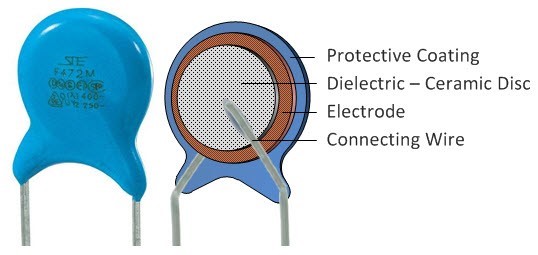

Ceramic Capacitor

Ceramic capacitors are most commonly used in every electrical device and it uses a ceramic material as the dielectric. The ceramic capacitor is a non-polar device that means they do not have polarities. So we can connect it in any direction on a circuit board.

Ceramic capacitors are available in the following shapes or forms: Ceramic disc capacitor, Ceramic tubular capacitor & Multilayer ceramic capacitor (MLCC)

Applications:

- Tone compensation

- Automatic volume control filtering

- Antenna coupling

- Resonant circuit

- Volume control RF bypass

- Lighting ballasts