Introduction

If you are a student, then the term test is always frightening to you. But, for the PCB designers, this term and its use are more important than anyone’s academic test. Because this makes the product development better and manageable. So, this article is all about the use of test points in PCB. However, before knowing its usage, one must need to understand the term ‘test point’.

What are the Test Points?

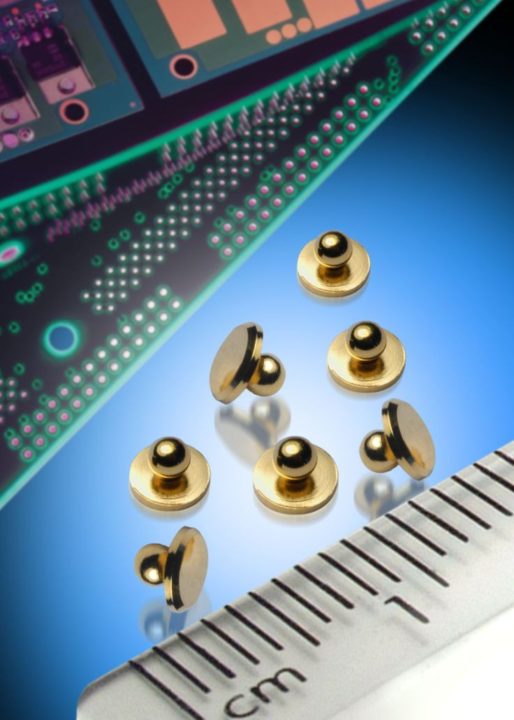

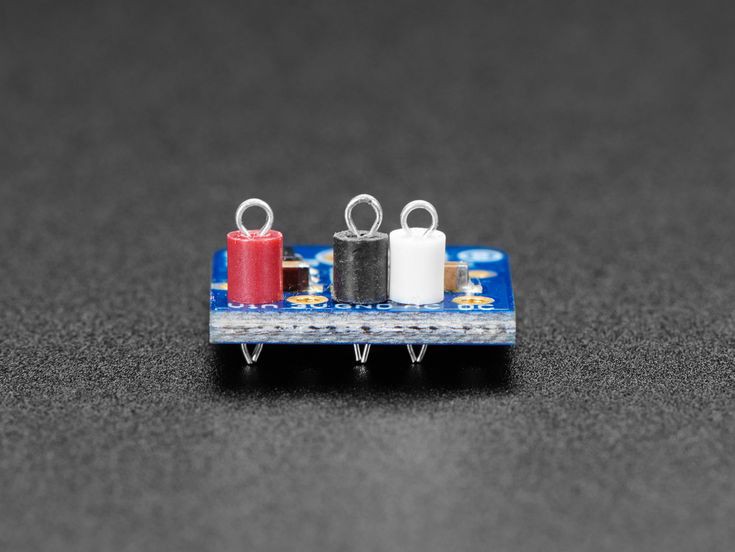

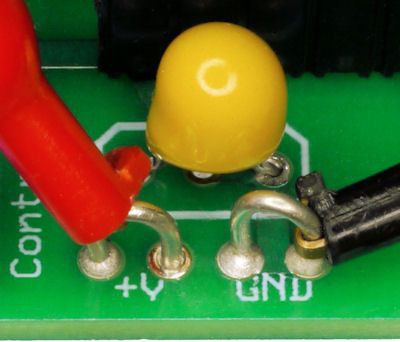

Test points in the PCB are the locations in the electronic circuitry that are used to test the device. I other words, it injects the test signals. Consequently, the device uses these test points to verify that if the circuit is working properly, or to analyze if it needs improvement. Moreover, they are used for necessary repairs of the device. To clarify, it’s a small region of exposed copper where you can connect a probe to test.

Types of Test Points

When talking about the classifications of test points, two types mainly exist

- Soldered Test Points: This type allows to easily suspect the errors with handheld equipment. These points have post soldered into them for editing the test leads.

- Automated Test Points: These are the test points that allow testing through automated test equipment. They have through-hole via, pins, and landing pads of metal. And, this adjusts the probes of the test system.

Test Systems

There are three types of test systems that ensure the safety and protection of the printed circuit Boards

- Bare Board Test: it is to make sure that all the nets in the boards have electrical connectivity. That’s why used after the fabrication of the board

- In-Circuit Test: This usually tests the bottom of the PCB board. But, if needed, it can test the top of both sides too. Hence, used after the assembling of PCB.

- Flying Probe: It is also used after assembling. However, it has 2 to 6 probes that can move around every test point, unlike the stationary probes that are used in In-Circuit Test.

Labeling of Test Points

Labeling makes the designer’s life easier. Also, it makes the testing quicker and simpler. If you have a large place, label it meaningfully to understand. But, if not, then you can also use numerical references to recognize.

Number of Test Points on the PCB

You can use enough test points that your circuit needs. It is good to ensure that every essential signal uses the test point. Usually, the test points are assembled at the bottom of the PCB. But, if the board is complex and tricky, then both sides of the board can be used for this purpose.

Benefits of the Test Points

When there is mass production of the PCBs, testing quickly is necessary to save time and cost. Since the testing is essential to verify the board and analyze the error if any. Therefore, test points are also crucial on the boards. It benefits to achieve the changes required. So, make sure that your PCB design has enough points to test.

Signals that Use Test Points

Interrupt lines, power supply rails, ground, reset lines, busses, ports, programming connections, and some other signals use these test points.