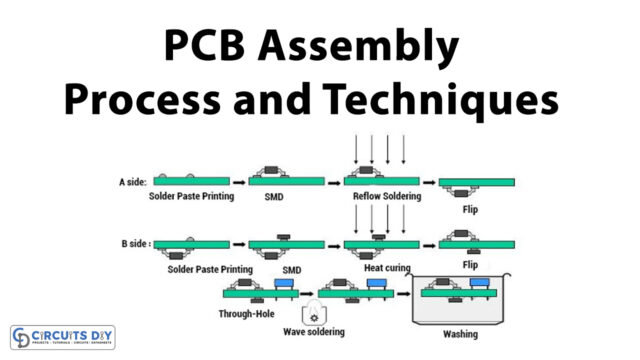

SMT PCB Reflow soldering is the modern mechanism for assembling most printed circuit boards today. Reflow soldering enables mass production at a very rapid rate by allowing the placement of the components to be separated from the actual soldering process. It provides a reliable way to solder a huge number of component and pad sizes, making it very easy to monitor and control the process. It is the penultimate stage in SMT PCB manufacturing, just before the PCB board is moved forward for further testing and inspections. So, In today’s article, we are going to learn in-depth about the SMT PCB reflow soldering process and the key performance indicators to keep an eye on.

SMT PCB Reflow Soldering

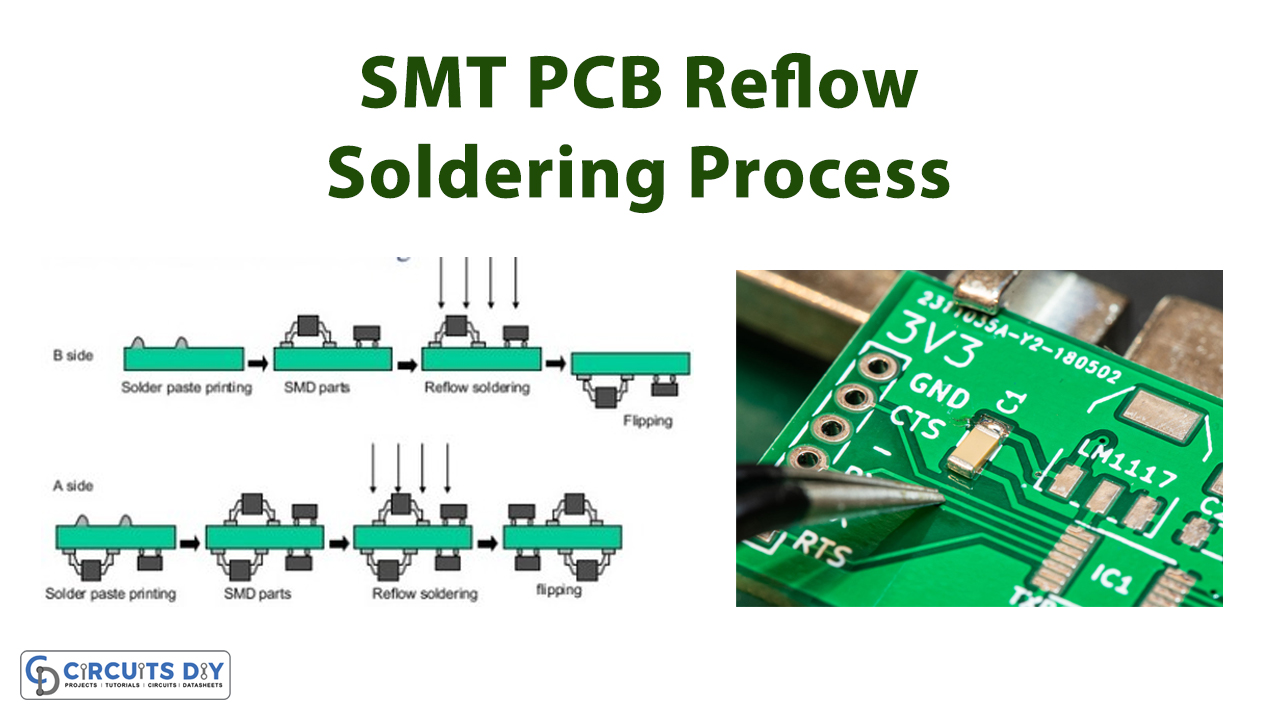

SMT Reflow soldering is a process in which a solder paste is used to permanently solder SMD components to their solder pads, after which the entire SMT PCB assembly is subjected to a controlled heat environment, within a heating unit called the reflow oven. The solder paste reflows in a molten state, creating permanent solder joints.

Pre-Reflow Preparation

Solder Paste Printing

SMT solder paste printing is the meticulous process of applying the right amount of solder paste on the solder pads. The most basic way of performing this task is to screen-print the solder paste onto the board through a stencil. Some manufacturers also prefer jet printing with this step. Solder Paste printing is the most sensitive part of the manufacturing process. Many PCB board defects often occur at this stage due to the use of substandard techniques and equipment.

The process comprises of spreading the solder paste onto the circuit board with the help of a manual or semi-automatic stencil printer. Here, a squeegee blade allows pressure for the spreading of the solder paste across the stencil which, in turn, allows to even the spread of solder paste on the PCB board. The blades are usually of metal. One can also use polyurethane for this purpose.

Pick & Place of SMT Components

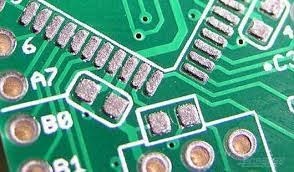

After the solder paste is on the PCB card; The board moves on to a pick and place machine (X – Y machine). The pick and place machine places the SMD parts on the solder pads covered with solder paste; here, the solder paste ensures that the SMD parts remain in place by the surface tension of the solder paste. This will help to prevent the SMT parts from moving and skewing.

Reflow Soldering Oven

A reflow oven is a small batch-box style oven for small lab scale operations. For larger design manufacturers, an inline reflow oven is often the best choice. An inline reflow oven; usually used in SMT PCB manufacturing, consists of a number of heating zones followed by cooling sections. The number of cooling and heating zones of a reflow soldering oven depends upon the length and throughput of the oven. During the reflow process, the zones are fed with a thermal setpoint using an onboard program. This set point corresponds to the temperature the circuit board should be exposed to as it passes through that zone.

SMT PCB Reflow Soldering Process

Pre-Heat

In the preheat stage, the board is brought steadily up to the required temperature. This part of the reflow soldering requires careful monitoring; As access heat to the board and components may result in SMD damage due to excessive thermal stress. The temperature should increase at a rate of 2 – 3 degrees per second

Thermal Soaking

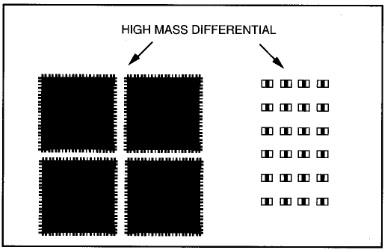

After the pre-heat stage. The PCB cards undergo a thermal soak. The main focus of this phase is to maintain the PCB’s SMD thermals at the same level it had reached in the pre-heating phase. We do this because of two reasons: first, to ensure that all the places on the PCB card are getting adequate heat and that there are no cold spots due to the shadowing effect. The second reason is to remove the solder paste solvents or volatiles, and also to activate the flux.

Reflow Stage

In the reflow stage, the solder is caused to melt and create the required solder joints. The actual reflow process involves the flux reducing the surface tension at the junction of the metals to accomplish metallurgical bonding, allowing the individual solder powder spheres to combine and melt. The reflow stage needs about 30 – 60 seconds.

Cooling Stage

After the reflow stage, the PCB board enters the cooling stage. Here, the melted solder sets down and seals the PCB parts in place. The cooling temperature of the PCB board is generally between 30 – 100 degrees and at a cooling rate of around 3 degrees per second.