Introduction

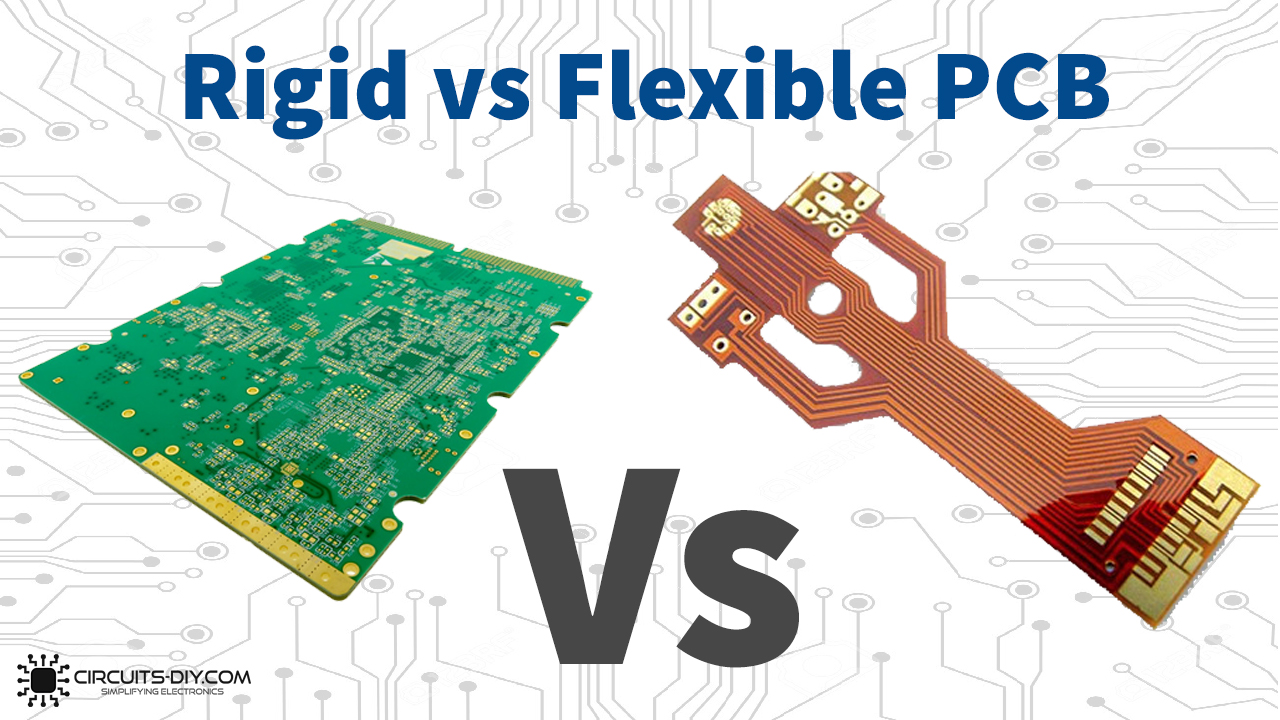

As we know that printed circuit boards have so many types. All the types have different purposes for different electronic circuits. In this article, we will discuss the two types, which are, rigid and flexible PCB boards. And, we will see the difference between them. Therefore, to discuss the differences, first, we need to elaborate on both sides.

PCBGoGo commits to meet the needs of its customers from different industries in terms of quality, delivery, cost-effectiveness, and any other demanding requests. As one of the most experienced PCB manufacturers in China. They pride themselves to be your best business partners as well as good friends in every aspect of your PCB needs.

Rigid PCB

Rigid PCBs are widely manufactured. And, It has a solid substrate or base material that prevents the board from any distortion. Moreover, Rigid PCBs can have a single, double, or multi-layer. Certainly, Rigid PCBs are made from copper tracks to connect the components on the board. So, these types of PCBs can not be modified after manufacture.

Advantages:

- Low Electronic noise

- Small and compact size

- Low cost

- More reliable

Disadvantages:

- No flexibility

- Not flexible for high speed circuitry

Applications:

- Aerospace devices

- Automotive circuits

- Medical Applications

- Industrial automation

Flexible PCB

Flexible printed circuits are also known as flex PCB. But, rather than printing photo imaging or laser imaging is used in the manufacturing process. A flex PCB has a metallic layer usually copper bounded with a dielectric layer, that is polyamide. The circuit is protected from electrical shorting. Therefore, the dielectric material is used for non-conductive areas.

Advantages:

- Less weight and space

- More reliable

- Thermal management

- Eliminate connectors

- High speed

- Reduces Assembly cost

Disadvantages:

- High cost

- More time consuming

- Difficult to repair

- Limited size

Application:

- In computer electronics

- Smartphones

- Medical Applications

Difference Between Rigid and Flexible PCB:

After that, above mention description, we can now make a difference between these two PCBs. Firstly, the manufacturing process of flexible is more complicated than rigid. Also, the cost of a flexible PCB is higher than a rigid PCB. Also, Flexible PCBs requires more time in manufacturing. Further, it’s difficult to repair and is still in the evolving period. However flexible PCBs are more reliable and have high speed. In other words, we can say that flexible PCBs would be more popular in the future technological world.

Where to use Rigid PCBs?

Firstly, the devices that need low-cost circuits like the motherboard of computer systems. However, they can be used for any kind of complex circuits. Because they have different types of boards that can be used for different objectives.

Where to use Flexible PCBs?

For ultra-compact and high-performance devices. For example, smartphones, cameras, tablets, wearable gadgets, GPS units, etc

Conclusion

To sum up, we can say that both types of printed circuit boards have a different purpose and applications cannot deny the importance of both. But, we can not deny the fact that flexible technology is still evolving stage.