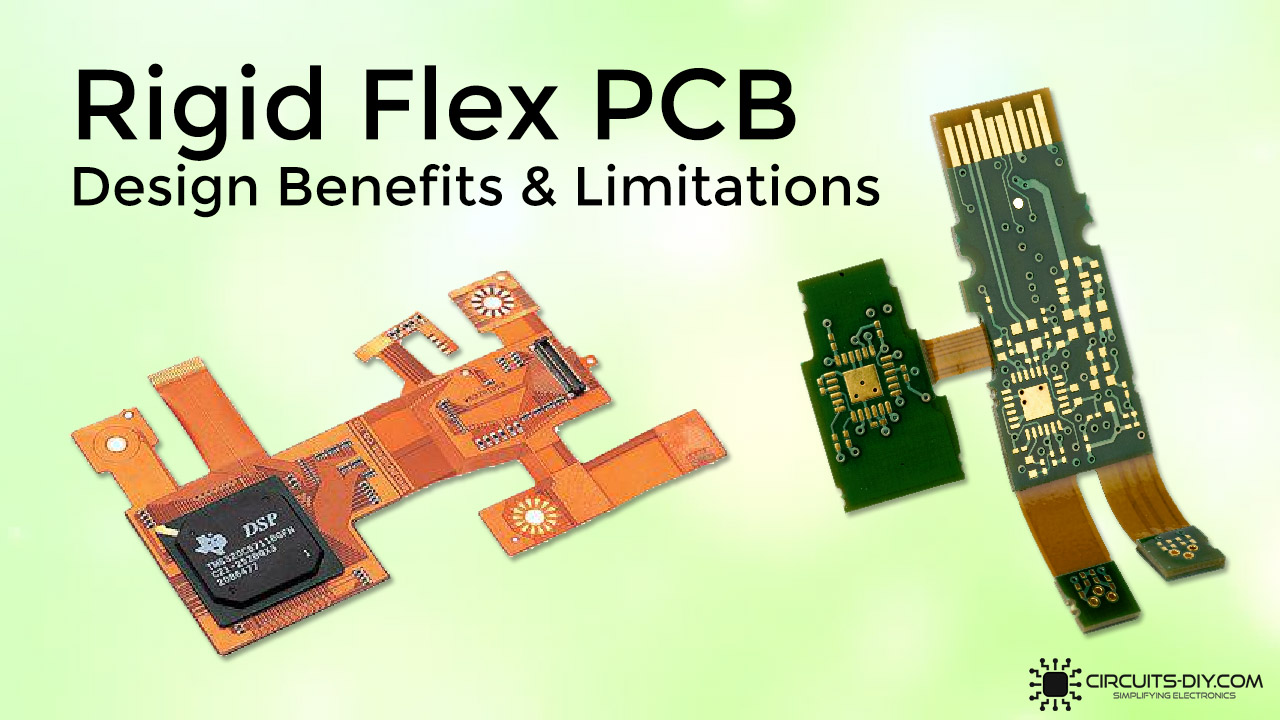

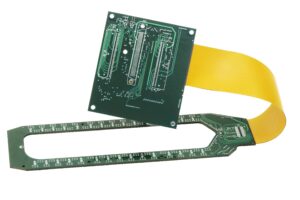

With the constant development in the domain of aerospace engineering or products. There is increasing pressure on the PCB design industry for lightweight, miniaturized, multifunction with high assembly densification PCB manufacturing solutions. Keeping in mind the overwhelming success of the flexible PCB, the next step in revolutionizing the PCB industry is the Rigid Flex PCB. So, in today’s tutorial, we are going to understand more about the Rigid flex PCB, just how exactly it works, its design benefits, and its limitations.

Rigid Flex PCB

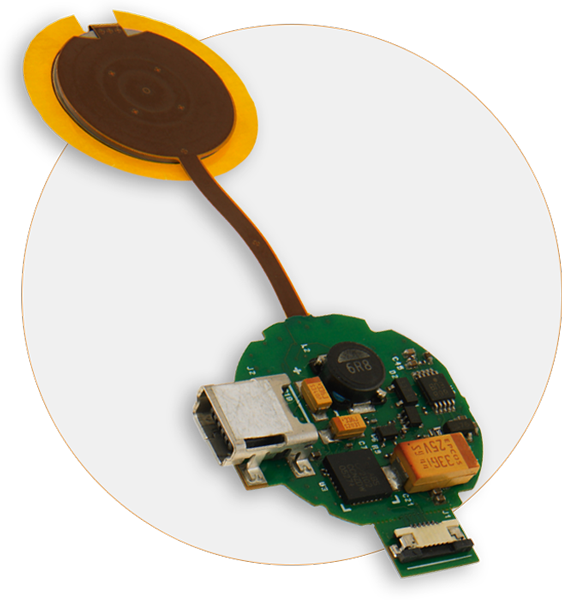

Rigid flex PCB is a hybrid PCB board that combines the best features from both rigid and flexible PCB format. These PCBs are rigid at some points on the board and flexible at others. Because of this, rigid flex circuits can be folded or continuously flexed while maintaining the shape of areas that need extra support. This two in one circuit interconnects through plated thru holes. Rigid flex circuits provide a higher component density and better quality control. The flexible layers are buried internally and completely penetrate the rigid sections of the PCB.

JLCPCB is the foremost PCB prototype & manufacturing company in china, providing us with the best service we have ever experienced regarding (Quality, Price Service & Time).

Types of Rigid Flex PCB

There are two main types of rigid flex PCBs:

1) Flex To Install

Flex to install board folds only once when the device is first assembled or removed. Besides this, the flex part of the board remains stable throughout use; apart from some movement, that may occur in the case of high oscillation applications.

2) Dynamic Flex

Dynamic Flex PCB is a special category of the rigid flex PCB family. Dynamic flex PCBs can fold and bend many times as per the design/product need during the end product use. It requires special consideration to ensure the flexible portion of the board can withstand repeated wear and tear. If dynamic flex PCB is designed using the correct bend radius. it can last over 10000 flex cycles.

Material Used in Rigid Flex PCB

Rigid flex PCBs composes primarily of a flexible dielectric film and a flexible adhesive film. Flexible dielectric mainly consists of polyester (Mylar), polyimide (Kapton), and fluoropolymer (PTFE). The following table represents the key performance criteria of the three types of dielectric films in rigid flex PCB.

| Performance Item | Polyester | Polyimide | Polytetrafluoroethylene |

|---|---|---|---|

| Limit Tension/N*mm-2 | 172 | 172 | 20.7 |

| Limit Elongation/% | 120 | 70 | 300 |

| Size Change After Etching/mm*m-1 | 5.0 | 2.5 | 5.0 |

| Relative Dielectric Constant/103Hz | 3.2 | 3.5 | 22.1 |

| Loss Angle Tangent/103Hz | 0.005 | 0.0025 | 0.0001 |

| Flammability | Flammable | Self-extinguishing | Inflammable |

| Dielectric Strength/mV*m | 300 | 275 | 17 |

| Moisture Absorption/% | <0.8 | 2.7 | 0.01 |

| Heat Resistance/°C | 150 | 400 | 260 |

Advantages of Using Rigid Flex PCB

Design Dynamism

Rigid Flex PCBs allow unlimited freedom of custom packaging geometry while retaining the precision density and repeatability of printed circuit boards.

High Mechanical Stability

The interchangeable layers of a rigid flex PCB allow the formation of a strong foundation. The rigid boards provides stability, while flexible boards provide the flexibility required for installation in small spaces

Cost Effective

The use of rigid flex PCBs and circuit boards can result in immense reduction in total PCB costs and expenditures. This makes the use of Rigid Flex PCBs very popular for large scale production operations

PCB Structural Support

Rigid flex PCB provides secure connections for other components onboard the PCB card, providing stability and polarity to them as well.

Applications

Rigid Flex PCBs have wide array of applications. From small scale consumer electronics such as laptops and motherboards to military applications such as boards for acoustic weaponry and UAV drones. Some other common examples of Rigid flex PCBs are as following:

- Smart Jackets

- Cell Phones

- Pacemakers

- CT Scanners

- ABS Sensors

- Digital Cameras

- Computer Servers

- USB and Ethernet

- Bar Code Scanners