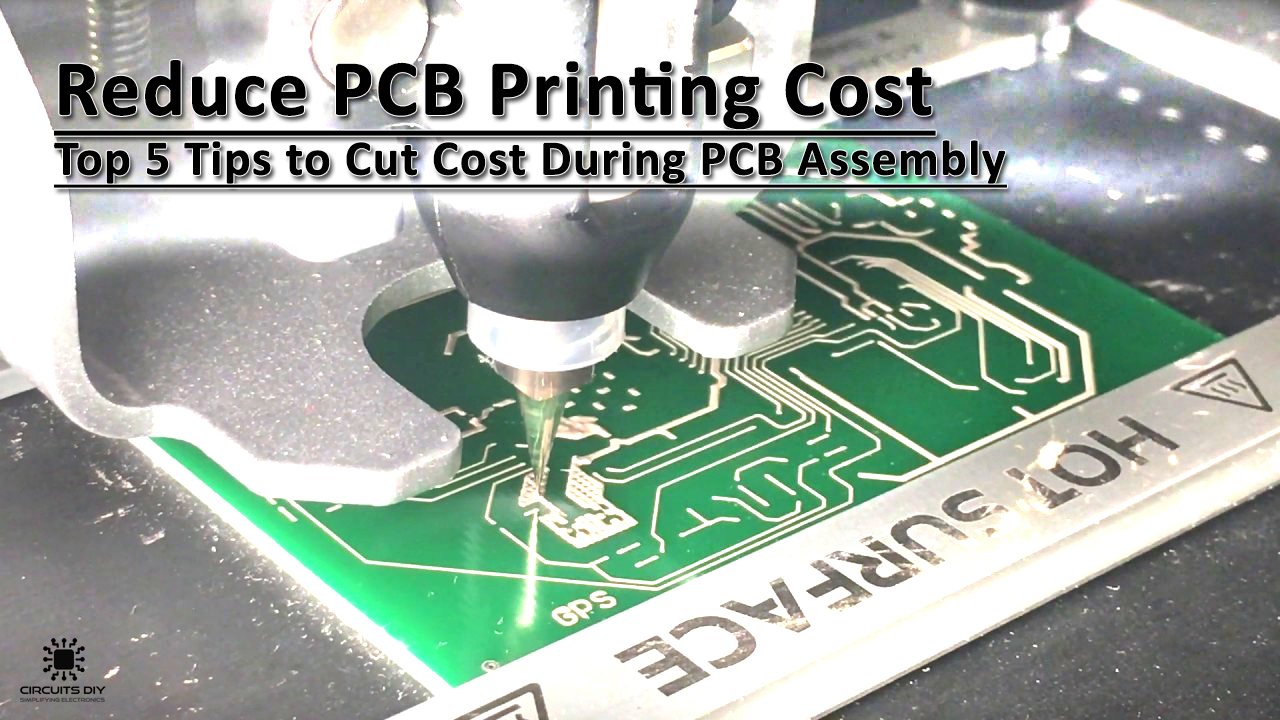

A great number of engineers, especially those who are just starting out in the field of PCB design usually ask themselves “Where can I find the cheapest PCB assembly service” or “How can I cut my PCB assembly cost?”. To be honest, there aren’t any absolutely “cheapest” PCB assembly services. In order to optimize the prize to design quality ratio, It is always recommended to find a balance between cost, assembly quality & Pre/post-sale customer service. However, you should always understand that PCB making can also incur some unnecessary costs due to incorrect judgment calls made in the design phase & by avoiding those you can reduce PCB printing cost while maintaining the assembly quality.

Reducing the printing cost of PCB boards is always about keeping things simple, concise & in line to achieve your design goals. PCB designing is usually seen as a complex operation of getting everything to fit in the smallest space or trying to space everything out as much as possible to make them easy to read & understand. In order to save on assembly price, you need to make your design decisions as smartly as possible, so as to maintain the design quality while keeping the cost as low as possible.

JLCPCB is the foremost PCB prototype & manufacturing company in china, providing us with the best service we have ever experienced regarding (Quality, Price Service & Time).

Top 5 Tips To Reduce PCB Printing Cost

1) Reduce Design Complexity as much as Possible

The first in reducing design cost is to see whether the design complexity can go down in any way possible. The Design for Manufacturing check or DFM check can help you in figuring this out. A lot of PCB assemblers offer free DFM check service, which you can rely on to reduce the assembly cost.

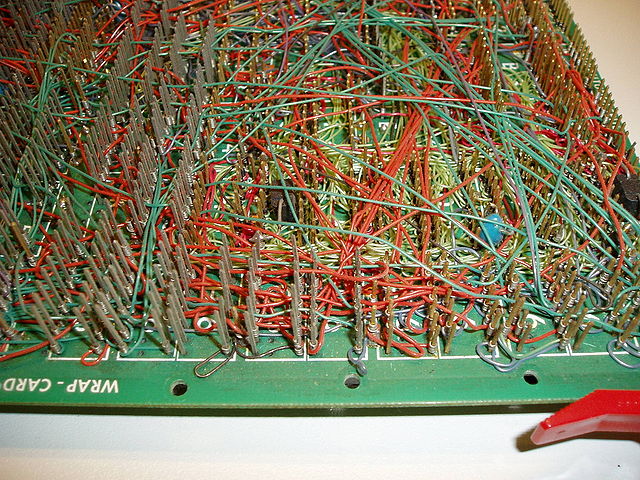

2) Cut Down On Layer Count If Possible

PCB fabrication costs adds up as the no. of design layers increases. If you are tight on budget, try to reduce the no. of design layers as much as possible. In other words, as more layers add to one circuit board, the higher the expense goes.

3) Prepare a Comprehensive & Complete BOM

The bill of materials or BOM is a comprehensive list of raw materials, items, assemblies and sub-assemblies, components, etc. for product manufacturing. It is better to add a replacement for every component in your BOM. With the proper BOM and replacement provided, a PCB assembler can provide a quote in just one or two days and start the production with your confirmation.

4) Always Size It Right

If your PCB is very complex & constitutes a small size, the time & effort to fabricate it will increase. Making PCBs very small & tight gets expensive pretty fast. So, try to save space where possible. If it all possible, make your PCB board a square or a rectangle. Complex shapes raise costs, especially if they’re very irregular.

5) Always Perform Tests & Inspections

To the tone of this guide, it may seem a bit counter intuitive to relate cost reduction with tests & inspections. Generally, inspection or test implementation increases the cost of production. but with respect to the intention of maintaining design quality, it is very important that you do not neglect important fabrication tests just to save a few bucks. Inspection or tests play a crucial role in contributing to the high quality of products by illuminating issues or mistakes in advance. So, make sure to have them performed.