SMT PCB production is a hectic process. With thousands of board orders coming each and every day; production speed becomes an essential factor in order to create and retain a profitable production margin. When it comes to the speed at which PCBs have to go through the production phase, one key contributing element is the Pick and Place machine. The Pick and Place machine plays a vital role in any assembly line; As, it allows SMD PCB components to be placed on a PCB card quickly and accurately. So, in today’s tutorial, we will understand the function of a pick and place machine in a PCB fabrication house and the factors that govern its operation.

What is a Pick And Place Machine?

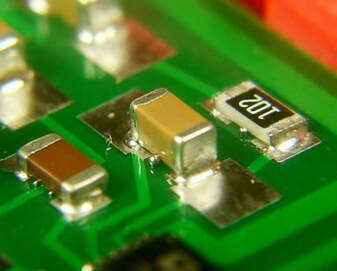

The pick and place machine is a highly sophisticated PCB assembly machine; that serves the purpose of picking up SMT/THT PCB parts and places them in their area of designation on the PCB board. Pick and place machines are usually stacked up with PCB components; generally, by the use of mechanical feeds. P&P machines typically have a head on a robotic servo arm that can reach all the reels, tubes, etc. The machine picks the PCB parts and then places them onto the board. Generally, the P&P machine head uses a small vacuum to pick the components up; and then release them onto the PCB board.

JLCPCB is the foremost PCB prototype & manufacturing company in china, providing us with the best service we have ever experienced regarding (Quality, Price Service & Time).

Key Factors To Consider During Pick And Place Process

1) Design of The PCB

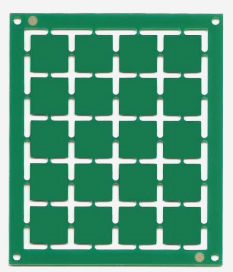

The design of the PCB the way the PCB grid is panelized has a major effect on the component placement process. Following factors must be taken into consideration before the component placement process:

Panel Size

The max size of the PCB board panel must conform with the placement scheme of the pick and place machine.

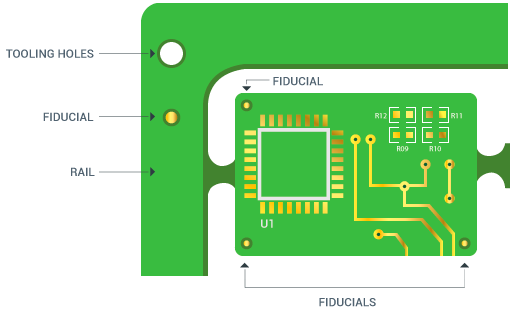

Fiducial Marks

fiducial marks are simple shapes and marks; that is traced within the track layers of the PCB card. Pick and Place machines use fiducial marks to make sure that all PCB components are accurately positioned on the board.

Component Size & Position

Designs with high component population density such as HDI (High Density Interconnect) PCBs have small components positioned close to larger components which must be taken into account when generating the placement program. The manufacturer must place all small PCB components before the larger parts; So as to ensure that they do not get disturbed. This is normally taken into account by the placement program optimizing software.

2) Type of Nozzle Used

With the abundance of tens of thousands of different SMD parts available in today’s market, pick and place machines must be able to adhere to a wide variety of nozzle shapes and sizes. Most nozzles implement vacuum to hold the component securely between the P&P steps but this does rely on the component having a flat top surface. The alternative is a gripper nozzle which grips the component sides and uses the vacuum to actuate the mechanism.

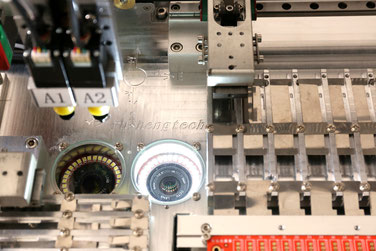

3) Visioning System

Every pick and place machine comes with some kind of visioning system for optical inspection of each individual component. This ensures that the dimensions of all the parts that will be on the PCB match. The optical inspection/visioning system also evaluates each individual component for any damage such as bent or lifted leads. Here, it is very important to carefully tune the tolerance profile parameter for each individual component; so as, to minimize the chance of an incorrect part being loaded on the PCB board.

4) PCB Support & Skewness Prevention

Generally, PCBs are made out of fairly rigid 1.6mm FR4 (flame retardant) material; A material that can hold its position fairly well during the component placement process. but, in case a thinner material is used or there are slots punched over the PCB array (in case of a PCB panel); the increasing pressuring from the P&P machine will cause the PCB to deflect; resulting in the PCB parts to skew & change their position.