Proper cleaning and maintenance of your PCB board is integral for maintaining its operational health. Neglecting or prolonging cleaning of your PCB boards may result in dust and grime getting in between the pads and traces, deteriorating its operation, or worse, causing the board to short and end up being dead. There are a wide variety of ways to clean your PCB board and not every cleaning method is right for every PCB board. Some PCBs may require special attention depending on the type of material used in manufacturing them. In today’s guide, we are going to go over a complete PCB cleaning 101 tutorial. This guide will cover every way you can keep your PCB dust free & clean.

PCBs or printed circuit boards serve as the backbone of any design industry. This allows you to connect passive and active components, and devices together, into a specific form to fit the design need. In order to keep these industry operations running as smoothly as possible, it is imperative to adhere to a strict SOP for PCB cleaning solutions.

PCB Cleaning 101: Best Methods to Keep Your PCB Spotless

1) Using Isopropyl Alcohol

Using Isopropyl Alcohol (IPA) for cleaning PCBs is a very common practice. IPA is the most efficient way of removing the most readily found PCB contaminants. In addition to this, isopropyl alcohol is electrically non-conductive and vaporizes quickly. Also, IPA has a very low blood toxicity level, meaning it will cause little to no harm if accidentally inhaled.

2) Using A Compressed Air Can

For simple repairs, compressed air provides an unobtrusive way to free up any dust resting on the electronics or inside the machines and blow it out. Use short bursts to spray the air inside the vent ports. If you’re not satisfied with the dust removed, open the device and work your way around the parts, carefully cleaning the circuitry with the air.

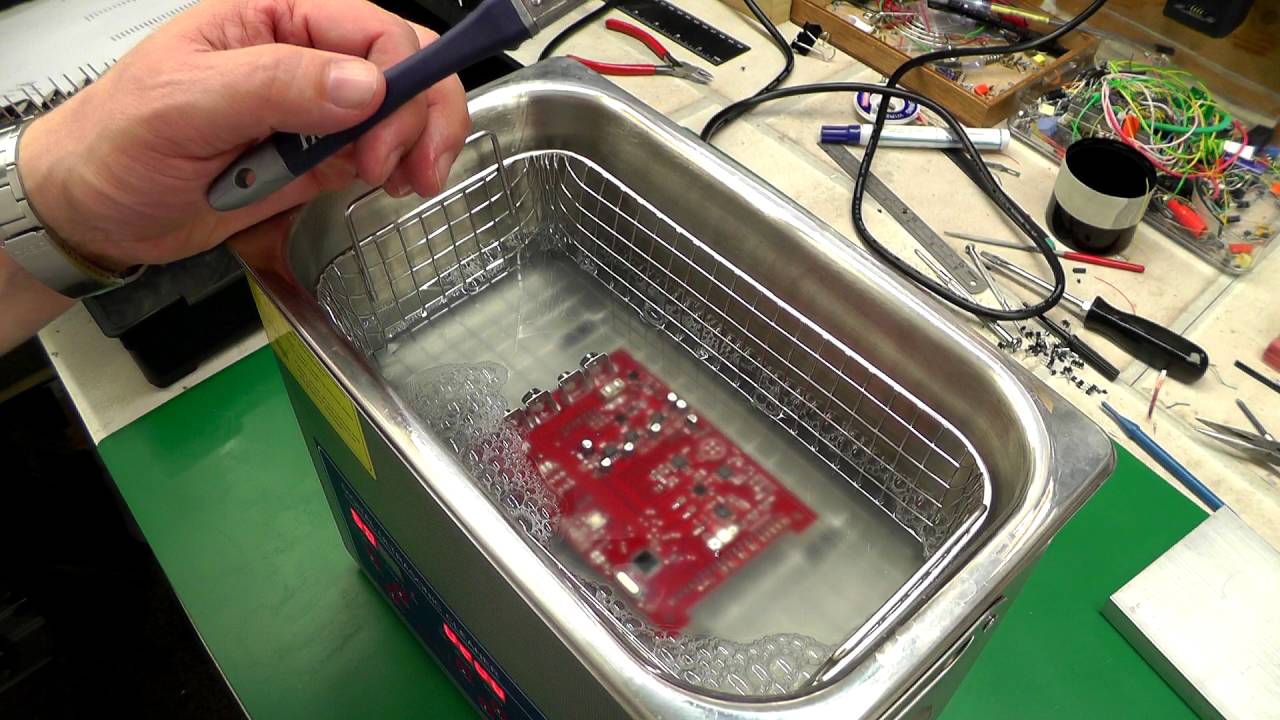

3) Ultrasonic PCB Cleaning

Ultrasonic PCB Cleaner can clean electronic PCB and spare parts of the circuit, remove dust, water, or any kind of useless material of the circuit. Cleaning a circuit board with an ultrasonic cleaner is the fastest and most efficient way to remove no clean flux, dirt, dust, and other small particles that have accumulated on the board.

4) Demineralized/Deionized Water

Deionized water is also a common preference for cleaning industry grade PCBs and electronics. Deionized water is a special category of treated water from which all ions have been removed, rendering it chargeless. It is made by taking conventional water and letting it exposed to electrically charged resins that will bind and attract to salts, and remove them from the water.

5) Soft Bristled Brush

Another cheap and easy way of cleaning your PCBs is to gently clean them using a soft bristled brush. Soft and gentle brushes generally allow you to easily clean dust, grime, excess solder flux left on the board by gently rubbing it against the board. Similarly, you can also use a lint free towel to clean your boards as well.