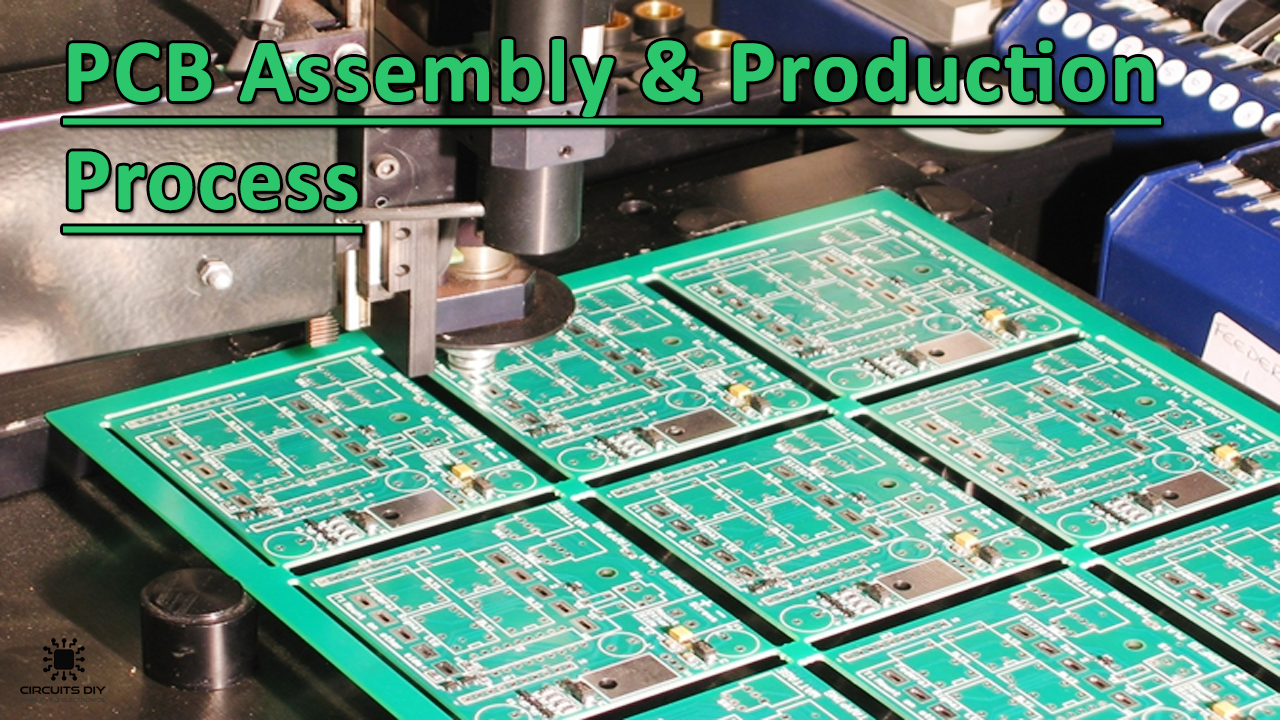

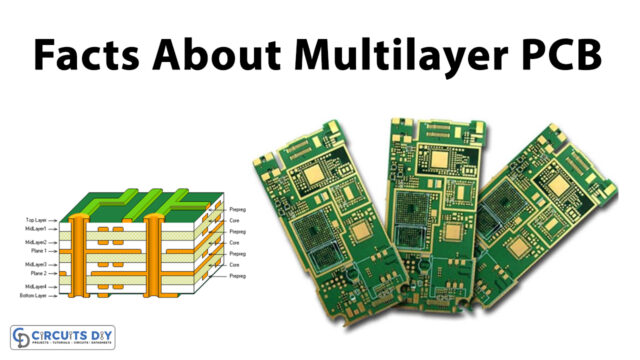

Printed Circuit Boards (PCBs) are electrical circuits created by laying printing tracks of a conductor such as copper on one or both sides of an insulating board. Printed circuit boards are used in all but the simplest electronic products. Mostly, PCBs are of composite material, composite epoxy, and fiberglass. A lot of effort and time goes into the wide-scale assembly of PCBs and the process itself is particularly complex. So, today we will take a deep dive into the steps involving PCB Assembly and Production Process.

PCB Assembly & Production Process or PCBA process, Is the process of soldering, assembling and arranging discrete components onto a PCB board/Card. Back in the day, PCB assembly was handled by using only soldering irons. But as the technology size is getting smaller & circuit complexity is increasing with the passage of time, it became imperative to introduce automotive/ mechanize methods to increase production efficiency. So how exactly are these boards made? The PCB assembly process consists of several automated and manual steps. To help you better understand the PCBA Process, the following is a step by step guide on PCB Assembly and Production Process.

“I have been cooperating with PCBWay for a long time and I have only positive impressions. Printed circuit boards are always of high enough quality. Printed circuit boards are made very quickly, as well as quickly delivered to Belarus. I selected this manufacturer as the main supplier of printed circuit boards for my Easy-SDR project. I did not regret this decision. I definitely recommend this company for cooperation”.

To Buy Custom built PCB’s at Low prices please visit: www.pcbway.com

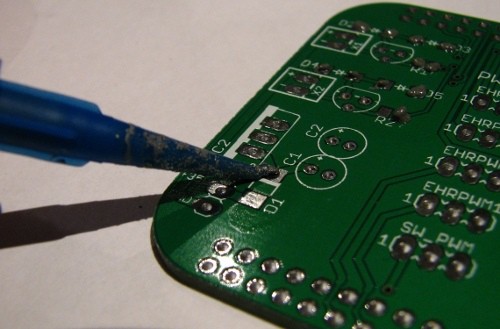

1) Stenciling of Solder Paste

Prior to the addition of the components to a board, solder paste needs to be fill into those areas of the board where solder is in need. This process is similar to screen-printing a shirt. Usually, a fixture holds the PCB and solder stencil in place. An applicator then applies solder paste on the intended areas in accurate amounts. The machine then spreads the paste across the stencil, applying it evenly to every open area. After removing the stencil, the solder paste remains in the set locations.

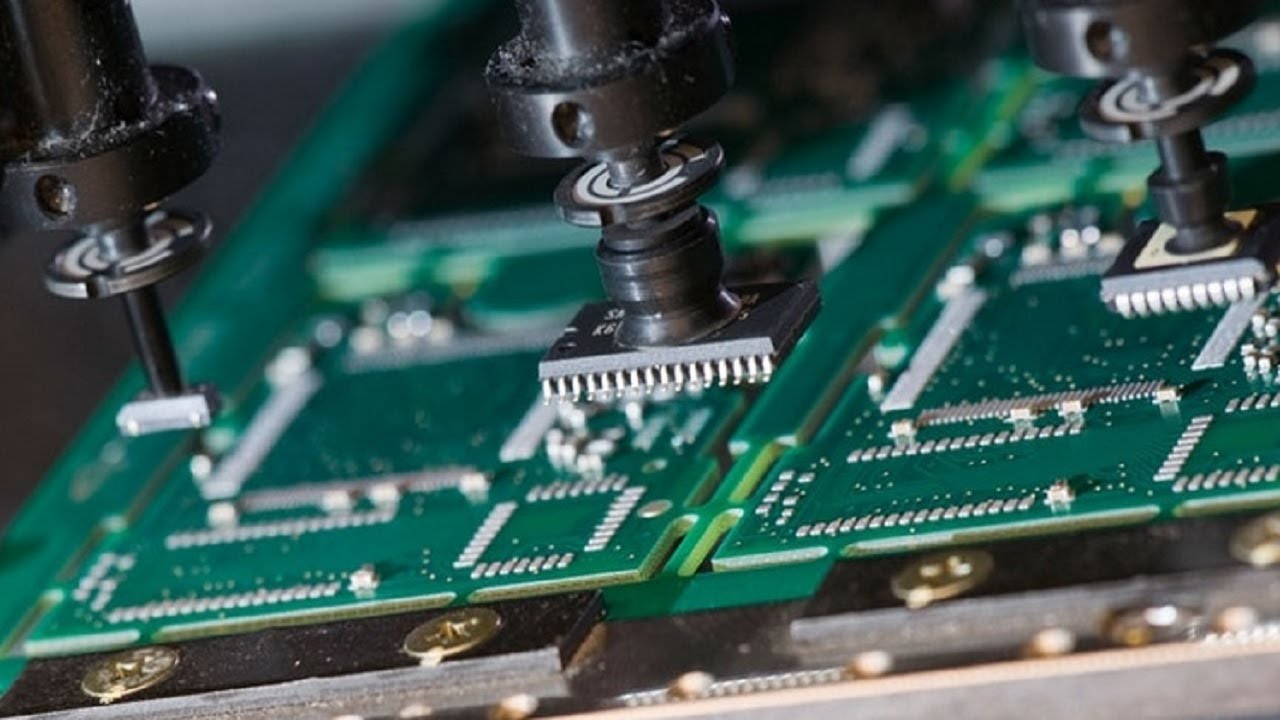

2) Pick & Place Process

During this part of the assembly process, the board with the solder paste goes through the pick and place process. The process begins by picking up a PCB board with a vacuum grip and moving it to the pick and place station. Then, a robot orients the PCB at the station and begins placing components on the PCB surface such as discrete components, surface mount components or SMDs from a reel line of discrete parts. The components remain in place by the surface tension of the solder paste which keeps them in place.

3) Reflow Soldering

Once the liquid solder paste and the components all are in place, they go through the reflow soldering process. Here, the PCB Card moves through a large reflow oven, similar to a commercial heavy-duty oven. This oven consists of a series of heaters which gradually heat the board to temperatures around 250°C or 480°F. This is hot enough to melt the solder in the solder paste. Once the solder has completely melted. The PCB goes through a series of coolers, which solidify the solder paste.

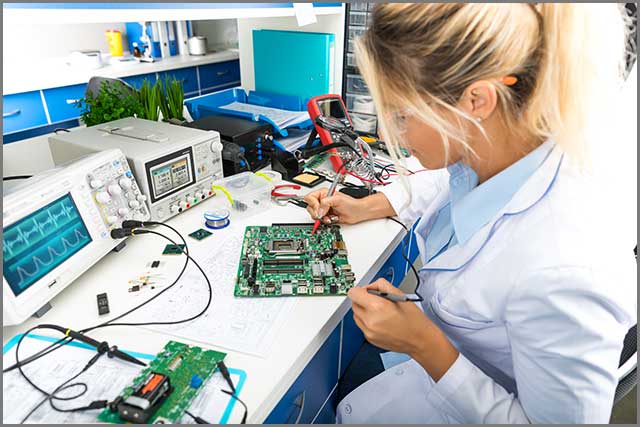

4) QA & Inspection

No PCBA process is ever over without thorough quality inspection. After soldering, the PCB card goes through a wide variety of assessment checks and inspections which includes manual checks to search shorts and loose connections, Optical Inspection to ensure solder health between every connection on the PCB and X-ray inspection in case of multilayer PCBs.

5) Functional Test

After quality assurance inspections, the PCB board goes through final functional testing. Here, the PCB is goes through a number of phases, in order to simulate the conditions in which it will operate outside the factory. It is necessary to test PCB Cards before they leave the factory to ensure customer satisfaction.

So, in conclusion, PCBA process revolves around the above given steps. Using these steps, PCB Manufacturers ensure the quality of their PCB boards.