Introduction to PCB

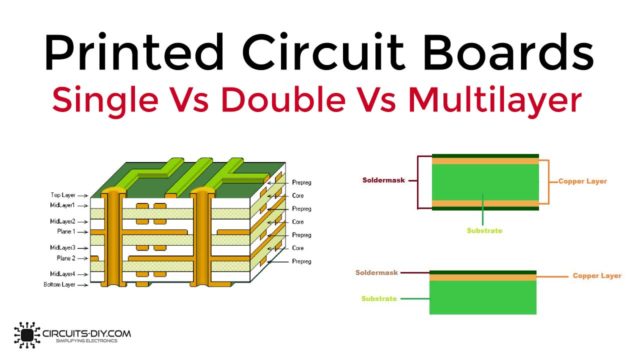

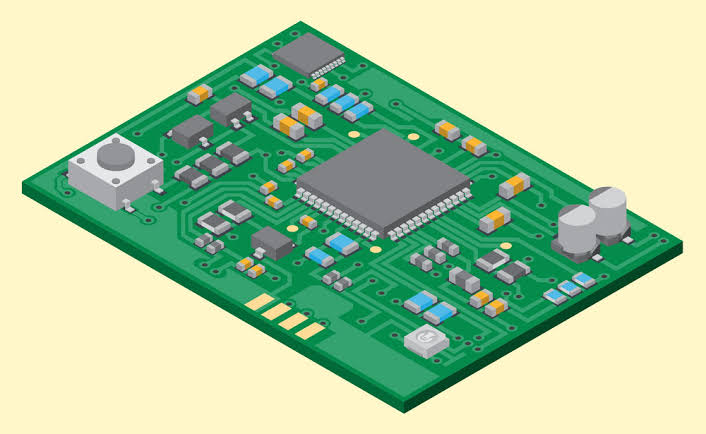

To give life to the electronic circuitry PCB prototype plays the main role. It follows the design process that converts an electronic schematic (designed by the circuit designer) into a real circuit board. However, there are three different types of PCB, a single-sided PCB, a double-sided PCB, and a multi-layer PCB.

What is the Prototype of PCB

A PCB prototype is like a trial board that is utilized for testing purposes. During the designing of any circuit, the designer needs to change numerous things, components, etc. That’s why the designer uses or builds a prototype for designing. It is very identical to the standard PCB. However, it lacks some elements

JLCPCB is the foremost PCB prototype & manufacturing company in china, providing us with the best service we have ever experienced regarding (Quality, Price Service & Time).

Why a designer needs a PCB Prototype?

You might think that designing the prototype must be a waste of time. But there is some reason and facts to understand that prototype is essential to make

- Error Detection: Through the prototype, one can easily detect errors. As a designer, we all know that the results of simulation and practical circuit can be very different. So, in this case, the prototype helps

- Improvement in Design: A designer can make alterations in the circuits and can improve the designs. One can add more new components to the prototype

- Save Time: If a designer makes a bigger circuit or many circuits of the same design. It would cause a lot of time to rebuild if the error would occur. So, the prototype saves the time

- Save Money: It would cause a lot of money if an error occurs in the design having the bulk of circuits prepared. Therefore, the prototype enables to save money

Forming cheap PCB Prototype:

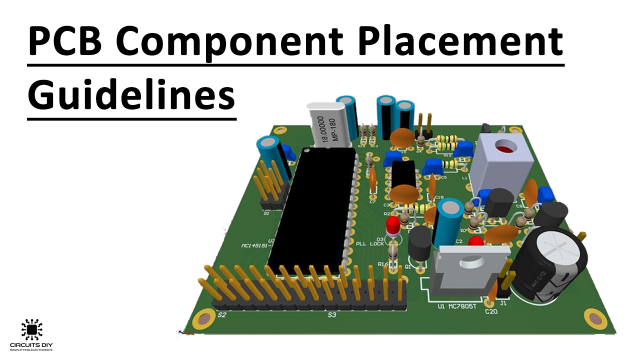

- To cost a cheap PCB prototype, one must need to design optimally. Some factors like size and shape, layer count, Via technology, etc define the cost of PCB. So, a designer must work on these factors

- Create a Bill of materials that include every necessary part of the design circuits. Include assemblers, part numbers, etc too. It should also contain the replacement element of components

- Order standard shapes, as they are always cheaper and not cost extra

- Choose the smallest surface area, it cost lower when reaches the manufacturing stage

- Order thin PCB. Use the single-layer design for low cost

- To cost cheaper, you can use vias and pad holes having the same size. The expense gets lower by using this technique

- Use surface mount technology, that provides low cost

- The market is full of different manufacturers. Only select the manufacturer that satisfies your budget and quality. To cost cheap go tolerant with order time

Conclusion

For electronic devices, the prototype is the major thing and plays a significant role in the best designs. But on the other hand, it’s not the final product of the design circuit. So, it must be of low cost. And that’s why several factors have been described above to make or it at a low cost. By working on these factors, a designer can skillfully make a low-cost PCB prototype.