Introduction

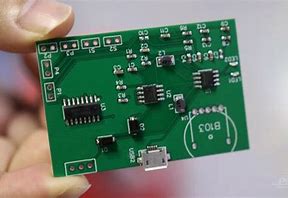

A printed circuit board is the fundamental part of electronic circuits. If the PCB is not of good quality, it may greatly harm the device. Hence the bad quality of PCB means a bad electronic device or circuit. Some major reasons like poor manufacturing and fabrication can affect the quality of PCB. But, one of the most harmful aspects that can be done by the designers is those mistakes that they do while designing or making Printed circuit boards. The bad quality design does not only harm the device but also questions the reliability of the Board. Moreover, the durability rate of boards is also questionable in those cases. Therefore, in this article, we will discuss the mistakes in making Printed circuit boards that should be avoidable by the designers while building any electronic device that uses PCB.

Major Mistakes to Avoid

So, here we are discussing some major mistakes that are done by the designers and manufacturers. avoiding these below-discussed mistakes can help to increase the life span of the board, increase reliability, enhance the quality, and can make the circuit more durable.

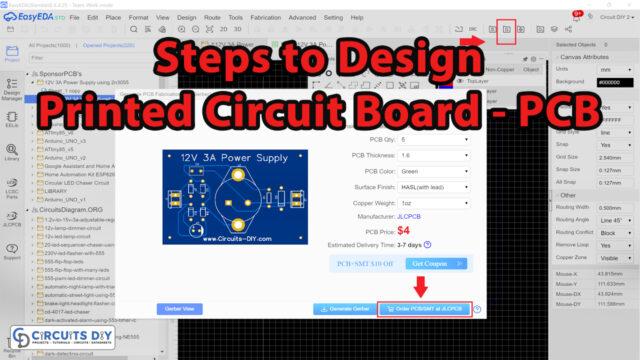

(1) Poor PCB Design Layout

Most of the problems that occur in the printed boards are because of their design. The design includes its circuit diagram and routing. Routing plays a major role and impacts the working of any device. If the routing is not done properly it may badly affect the board. Routing means the placement of vias that connects the components. If the route traces are not properly placed with appropriate length, width, and spaces, it may offer the hope problem in the future. Therefore, it should be done effectively.

(2) Ineffective Tools in Manufacturing

Improper tools can badly affect the circuit’s performance. Tools that comprise the manufacturing equipment, and also stencils. The wrong tools can only create a bad quality printed circuit board. Furthermore, it may also raise the cost of the circuit. So, it is always excellent to use the best tool available. Do peculiar research and investigate what tools are more assuring for your printed circuit board.

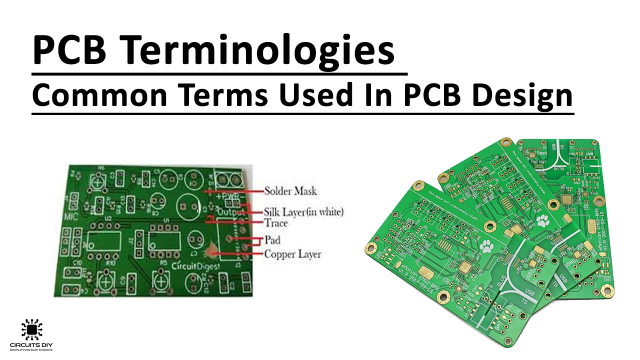

(3) Improper Thickness of Copper in Fabrication

Printed circuit boards of different types require different types of thickness. While fabrication one must be specific about the parameters. Several designers use only an ounce of copper. This is not sufficient for the board. As a result, poor plating in the holes may happen. So, it is prescribed to apply 1 or 2 ounces per square ft.

(4) No Prototype for Testing

A prototype helps to test the device and if there are any mistakes, it allows to remove errors. Therefore, to avoid errors and mistakes, the designers need to test their design on the prototype board. Hence before attaching it to the device, it is beneficial to examine the design practically. It may also serve to save the device from any damage.

(5) Lack of Communication between Teams

The team is obliged to communicate with each other. While working on a large project, pressure and stress is the primary issue. And, designers do multitask. This results in low productivity and can build extravagant PCBs. Therefore, members of the team must need to divide the work accordingly. And, together make the attainable timeline to complete the project. This would help to give more motivation and a better product in the end.