Introduction

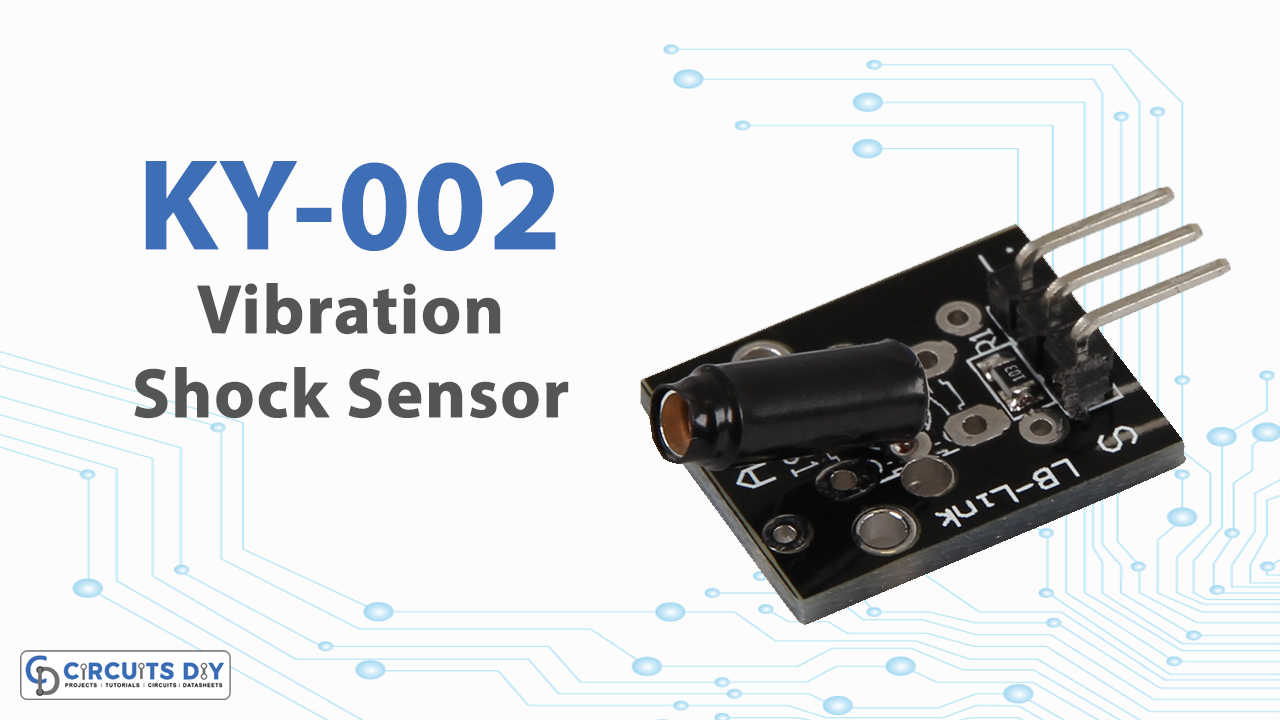

A vibration sensor is a device that detects the magnitude and frequency of vibration in a system. We may utilize vibration sensors to provide maintenance teams with insight into situations within important assets that could contribute to equipment failure, allowing them to forecast machinery maintenance, minimize overall costs, and improve machine performance. This article is about the KY-002 vibration sensor

Hardware Overview of KY-002 Vibration Sensor

A conductive wire coil is enclosed inside the plastic casing of the KY-002 Vibration Shock Sensor. The coil bends and touches an electrode when the sensor is jolted, allowing current to flow between the coil and the electrode.

There is a black tube that you can see outside the sensor. A metal spring connected to the ground wrapped around a metal rod connected to a positive voltage within that black tube. When the spring bends because of a powerful jolt or vibration, it contacts the rod, allowing current to flow between the rod and the spring.

Features

- Capacitive Vibration Sensor

- Omnidirectional, Vibration from any angle can trigger the sensor.

- This Vibration switch can be used as a trigger for the small current circuit.

- Vibration switch, vibration sensor, shock sensor.

Specifications

- Material: FR4

- Length: 24mm

- Width: 15mm

- Height: 15mm

- Operating voltage: 3.3 V – 5 V.

- Temperature Measurement Range: -55 ℃ ~ + 125 ℃

- Range Accuracy: ±0.5 ℃

- Max current:10mA

Pinout of KY-002 Sensor

| Pin Name | Description |

|---|---|

| Ground | To connect with the microcontroller or system’s ground |

| Power | Needs to be connected with a supply of 5V |

| Signal | The output of the module needs to be connected to the input pin of the controller |

Applications of Vibration Sensor

Earthquake Monitoring System

We can measure earthquakes by using a vibration sensor, that detects the vibrations generated by seismic waves. These waves can be natural because of earthquakes or can be produced b by some human activities.