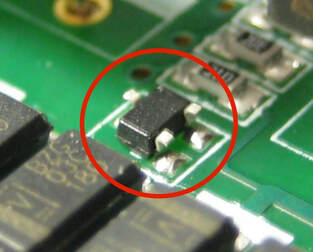

Maintaining a certain caliber of floor conditions is critical in SMT PCB fabrication. The process of SMT manufacturing can be affected by the slightest changes in the environmental factors surrounding it. Big name SMT manufacturers spend big bucks on implementing cutting edge technology to control the key environmental factors of the SMT floor and understand that keeping a keen eye on these factors will help in enhancing the floor productivity by reducing delays due to SMT KPI faults. In today’s article, we will go over the key environmental factors that govern an SMT floor’s productivity.

SMT PCB Assembly

SMT PCB Manufacturing and assembly is simply a structured chain process in which electronic PCBs are assembled by the use of automatic machines that place the SMD parts on the surface of the PCB. The process of SMT PCB manufacturing & assembly does not only includes placing and soldering of components but also a wide array of productions.

Key Environmental Factors To Control During SMT Manufacturing

Following are the Key Environmental factors that need to be control on an SMT floor

1) Relative Humidity (RH%)

The relative humidity is the ratio of the partial pressure of water vapor to the equilibrium vapor pressure of water at the same temperature. Simply put, Rh is an analysis of the amount of water vapor in the air. Humidity has a major impact on the workings of the SMT floor, especially during the process of reflow soldering. By default, the desirable humidity range on the SMT floor is between 35% – 65%. Any value above or below that humidity range may cause serious damage to the SMT fabrication process.

High Humidity (Above 65%)

Humidity Levels above 65% can cause an array of issues on the SMT floor. A few of them are as following:

- Slumping: Slumping occurs when the solder paste absorbs way too much water and causes bridging during the reflow process.

- Solderballing: Solder balling is basically the poor coalescing between the solder paste and the SMT part due to an increase in water absorption during the reflow process by the solder paste.

- Out-gassing: Out gassing occurs when too much water creeps under surface mounts, especially BGAs, and causes pressure to build up. In some cases, covers can be blown off and cracks can appear, causing the BGA/IC to go dead.

Low Humidity (Below 35%)

Humidity levels that are below a certain desirable threshold can also hurt the SMT PCB production process as well. A few complications are as following:

- If the humidity level is far below the optimum range the solder flux will evaporate far too quickly, this in turn will create poor release from stencils and insufficient solder SMT joint defects.

2) Temperature

The temperature of the SMT workshop has a major effect on solder paste activity. in addition to this, it also has an impact on the activity of some of the solvent in the scaling powder. As a general rule of thumb, an optimum temperature range of 22°C – 25°C should remain in check at all times during SMT work floor activities.

Following are some of the problems caused by irregular temperature flow during SMT fabrication.

High Temperature (Above 25°C)

With the increase in temperature comes a wide variety of SMT fabrication issues such as decreased solder paste viscosity. This, in turn, causes a wide variety of solder paste reflow issues such as solder paste smearing and slumping. If left unchecked, this can result in solder paste bridging and other solder balling defects such as voiding. High temperatures might also result in extra oxidation of the solder, which can compromise solderability. Resulting in poor SMD connections.

Low Temperature (Below 22°C)

Allowing the temperature to drop below a certain threshold will also cause a number of fabrication issues. If the temperature is too low, solder paste viscosity may increase rapidly. Resulting in poor printing behavior, such as release and rolling of solder paste print, as well as print voiding, in which the solder paste is too solid to print correctly.