Making Printed circuit boards is not a simple task, it requires a lot of brainwork, hard work, and energy. The single PCB needs to go through a lot of different processes. From drilling to etching, from outer layer inspection to solder mask coating, and from final cleaning to fabrication. Hence, it requires patience and so time. It gets difficult for a normal designer to do all of this while making other designs. Thus, companies like JLCPCB make it easier, providing low-cost, high-quality, efficient manufacturing and assembly of PCB that makes them promising to use.

Why JLCPCB?

Even though JLCPCB makes board development easier at a reasonable cost. Some more capabilities make them stand higher among others to call for them.

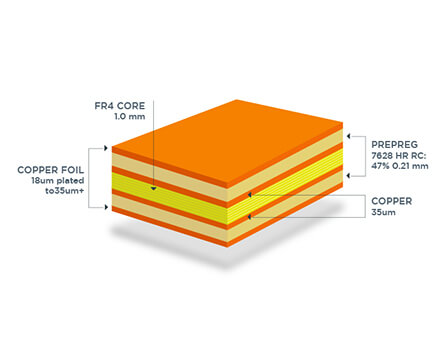

The Material

JLCPCB service uses FR4 material, FR4-Standard Tg 140C. FR4 is a code name for Epoxy Glass material, while Tg is the Glass Transition Temperature, the base material parameter for the temperature in degrees Celsius. This transition temperature is one of the most significant properties of any epoxy and is the region of temperature where the polymer goes from hard material to soft, and therefore board material must be flame-resistant, and should not be burned at a specific temperature. JLCPCB uses the best material for that purpose.

High-Quality Board

Any designer or customer is always concerned about the quality of the boards. A good circuit can get damaged if the quality is not good or if the board could not able to take temperature or pressure. So, JLCPCB manufactures high-quality boards that out-stand among others.

Solder Mask and Silk Screen

These PCBs come with silkscreen and solder mask that enhance the strength of the PCB boards and give insulation between the copper layers for any case when conductive material touches the board

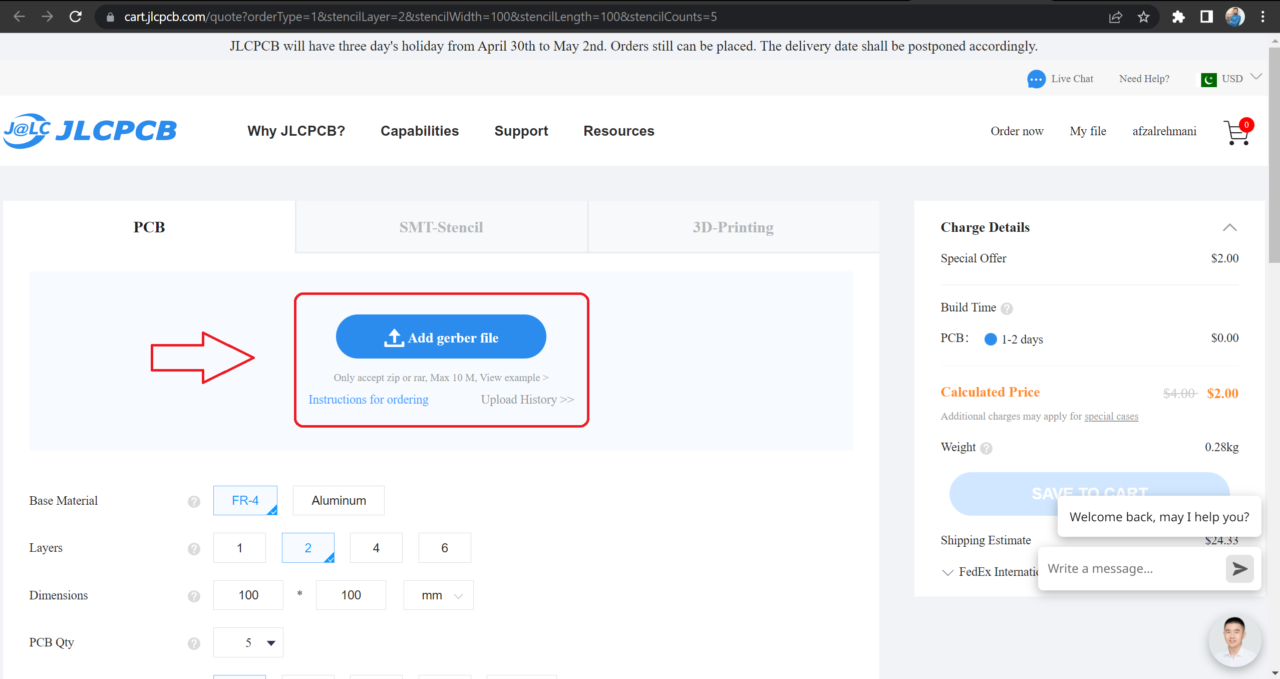

A useful option for Uploading Gerber File

A Gerber file is a great idea to see what your actual product would look like. Thus it decreases the risk. So, JLCPCB provides the useful option of uploading of Gerber file where you can estimate the number of traces on your PCB.

Reasonable Cost

You may get surprised but this fabrication company provides exceptional quality at very reasonable prices. And, you may not get the same quality, customer board, at these prices from any other fabrication house. This may be the greatest reason for them to recommend it.

Conclusion

If we see the above cons of JLCPCB, there would be no doubt to claim that the fabrication house is the effective way of getting your PCB done. The company is a quick solution for beginners having a low budget for their projects, and are trying to make printed boards at a cheap cost. Moreover, the company also does not disappoint the industrial applications.