Introduction

Controlling the temperature for your circuit in a Printed circuit board is necessary. Because the high temperatures can damage the PCBs. It’s crucial to maintain temperature, yet difficult to monitor it. So, in this article, we will learn about the factors that generate the temperature. We will examine how to measure the PCB temperature. Further, We will discuss the importance to monitor that temperature. Also, we will evaluate how to monitor that temperature.

Factors that Generate Temperature in PCB

Numerous factors induce heat. One of the most prominent factors that dissipate heat is the components mounted on the printed circuit boards. Components like integrated circuits, transformers, etc dissipate heat. However, this can be diminished or reduced by using the heat sinks in the circuitry. Another critical factor is soldering. During the soldering of the PCB, the machine dissipates some heat that gets induced in the circuit. Moreover, drilling may also increase the temperature in the PCB. Hence, for the survival of PCB, designers, and engineers must have to overcome this issue.

Measurement of PCB Temperature

Most of the temperature growth in the PCB shifts to the temperature sensors of the circuit. Since the ground pins of the PCB are on the substrate area. That’s why there is the least thermal resistance between the source and the sensor. To measure the temperature efficiently on the PCB. Use the following steps:

- Make the ground plane common for the temperature sensor and the heat source. Remember, that the Heat source is the heat dissipating components of the circuit.

- Connect all the ground pins of the heat sources and the temperature sensor on that ground plane.

- Try to keep the heat source and temperature sensor as close as possible.

Importance of Monitoring the Temperature

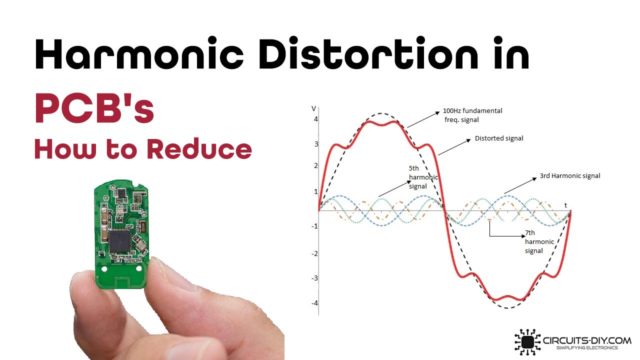

It is necessary to monitor the temperature in the PCB. Because it plays the important role in damaging the printed circuit boards. It damages the structural integrity of the PCB and harms the layers present in the circuit board. Also, it disrupts the circuit lines. As a result, the circuit may not be adequate for frequency shifts and distortions. It can also affect the material of the layers. The high heat dissipation may cause the expansion of the material that has been used in the manufacturing process. It may cause oxidation, which may result in the loss of transmission lines.

How to Monitor PCB Temperature

It’s an idiom that the solution to every problem comes before the problem. Hence, every trouble has a solution. So, the designer can also solve this problem of temperature by taking some measures:

- Since many of the components dissipates the heat. Therefore, the designer must need to use heat sinks. It prevents the expansion of the heat.

- The designer can also use fans to cool down the circuit board. It may help to extend the life of the pro ted circuit boards.

- High temperatures can also be reduced by applying the laminated. It helps to secure the board from overheating.

- Increasing the thickness of the plate is another method to reduce the temperature. It helps to conduct less heat in a circuit.

- Replacement of components also influences the PCB. The closer components may produce the skin effect. This effect increases trace resistance. Hence, increases the heat. This is more popular in circuits that use high frequency.