Overview

Computer Numerical Control (CNC) machines have revolutionized the manufacturing industry by automating precision tasks that were once labor-intensive and prone to human error. Whether you’re a seasoned CNC operator or a beginner looking to harness the power of these incredible machines, there are essential tips and techniques to ensure your success. In this article, we’ll delve into how to use a CNC machine effectively, helping you produce accurate, high-quality work pieces.

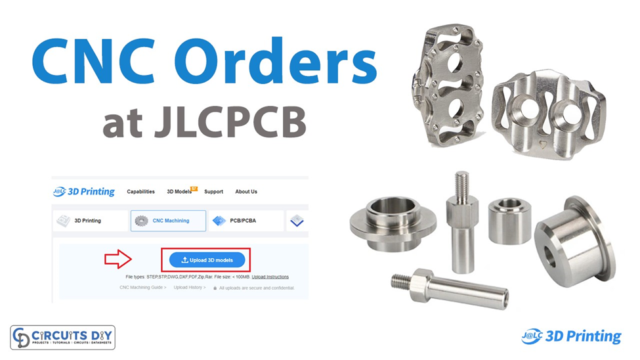

CNC machining at JLCPCB, a leading manufacturer in the printed circuit board (PCB) industry, exemplifies precision and efficiency. Utilizing cutting-edge Computer Numerical Control technology, JLCPCB ensures the production of high-quality PCBs that meet the exacting standards of modern electronics. Their CNC machines are adept at fabricating intricate designs and complex components with impeccable accuracy. Whether it’s a prototype or a large-scale production run, JLCPCB’s CNC machining capabilities play a crucial role in delivering reliable and cost-effective PCB solutions for a diverse range of applications.

Tips for CNC Machine

1. Understand the Basics

Before diving into CNC machining, it’s crucial to have a solid understanding of the fundamentals. CNC machines use computer programs to control the movement of cutting tools, allowing for precise and repeatable operations. Familiarize yourself with the key components of a CNC machine, including the controller, worktable, cutting tool, and the computer software that generates the toolpaths.

2. Choose the Right Toolpath Software

Selecting the right Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software is paramount. CAD software helps you design your part, while CAM software generates the toolpaths required for CNC machining. Popular options include AutoCAD, SolidWorks, Fusion 360, and Mastercam. Invest time in learning and mastering the software that suits your needs to efficiently create toolpaths.

3. Develop a Clear Plan

Planning is crucial in CNC machining. Define your project’s objectives, including materials, dimensions, and tolerances. Consider the type of CNC machine you’ll be using, whether it’s a milling machine, lathe, or router, and choose the appropriate tooling and cutting speeds accordingly.

4. Material Selection

Selecting the right material is vital for CNC machining success. Factors like the material’s hardness, machinability, and thermal conductivity can significantly impact the machining process. Ensure that the chosen material suits your project’s requirements and that your CNC machine can handle it effectively.

5. Secure Workpiece and Tooling

Properly securing the workpiece and tooling is essential to prevent accidents and ensure accurate machining. Use clamps, vises, or other fixtures to hold the workpiece securely in place. Make sure the cutting tool is correctly installed and tightened according to the manufacturer’s guidelines.

6. Zero Point Setup

Establishing a precise zero point, also known as a reference point, is crucial. This point serves as the starting position for the CNC machine. Carefully set the zero point on the workpiece and the CNC machine’s controller to ensure the machining process starts accurately.

7. Test Runs and Feeds

Before starting the actual machining, perform test runs to verify the toolpaths and make any necessary adjustments. Pay close attention to cutting speeds, feeds, and depth of cuts. Start with conservative settings and gradually increase them as you gain confidence in the process.

8. Monitor the Process

During the CNC machining operation, monitor the process closely. Be prepared to intervene if any issues arise, such as tool wear or chip buildup. Regularly inspect the workpiece for dimensional accuracy and quality.

9. Maintain and Clean Your CNC Machine

Routine maintenance is essential to keep your CNC machine operating at peak efficiency. Clean the machine regularly to remove debris and coolant buildup. Lubricate moving parts as recommended by the manufacturer to prevent premature wear and ensure smooth operation. Using an oscilloscope in maintenance also provides substantial benefits. It aids in identifying electrical problems in equipment, facilitating prompt repairs, and averting significant malfunctions.

10. Safety First

Safety should always be a top priority when using CNC machines. Wear appropriate personal protective equipment (PPE), such as safety glasses, hearing protection, and gloves. Familiarize yourself with emergency stop procedures and be cautious around moving parts.

Conclusion

Using a CNC machine effectively requires a combination of knowledge, skill, and attention to detail. By understanding the basics, selecting the right software, planning your projects, and following these tips, you can harness the full potential of CNC machining. Whether you’re crafting intricate parts or mass-producing components, these effective tips will help you achieve accurate and high-quality results while ensuring safety in your workshop. So, go ahead, embrace the world of CNC machining, and watch your precision engineering dreams become a reality.