If you are a pro in making electronic circuits and devices, you must have used the soldering iron to solder electronic components for your devices and circuits. While using the iron sometimes it happens that your iron doesn’t heat properly, and so does the soldering wire. In that case, the soldering wire doesn’t melt properly which ultimately is not promising for any circuit. It can damage the whole circuit and can also be the reason for discontinuity of paths, in the case of Vero boards. However, it is also not encouraging to buy the iron again and again. The only solution is to fix this problem And, for this, in this tutorial, we are going to “Repair Soldering Iron Not Heating?”

Figuring out the Problem

The soldering iron consist of the heating element and the temperature adjustment control. While soldering, if you realized that the tip of the iron is not getting enough temperature to melt the wire, know that, there is a problem inside. Now you have to repair the iron. For this, you need the required materials. So, the following are the components that you need.

Hardware Required

| S.no | Component | Value | Qty |

|---|---|---|---|

| 1. | Heating Element | 60w | 1 |

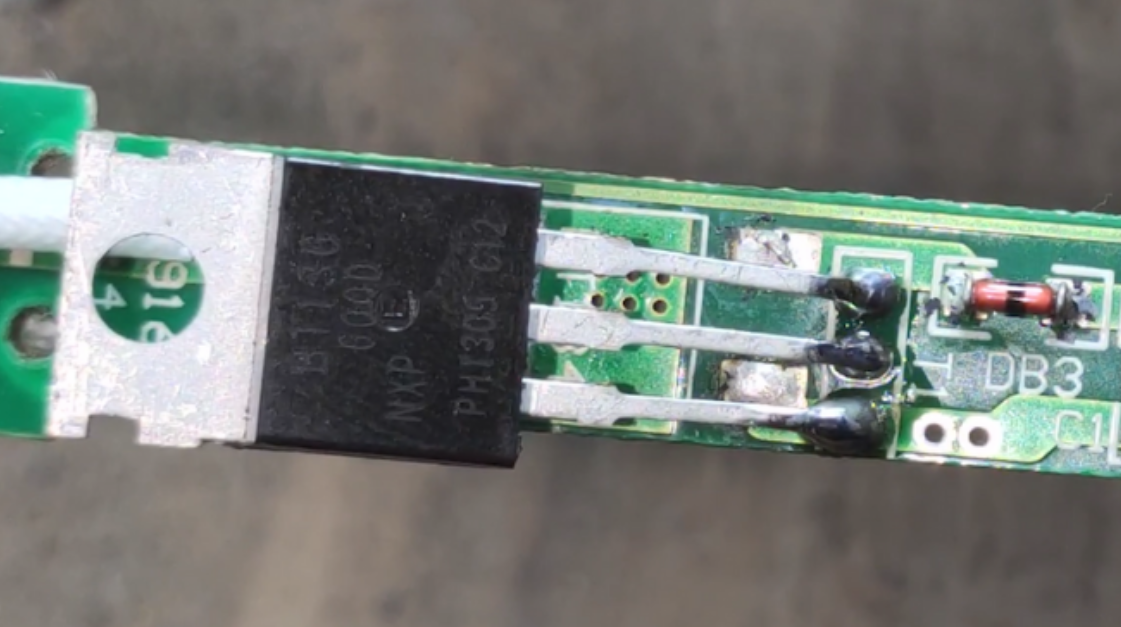

| 2. | Triac | BT136 | 1 |

Steps to Repair the Soldeing Iron

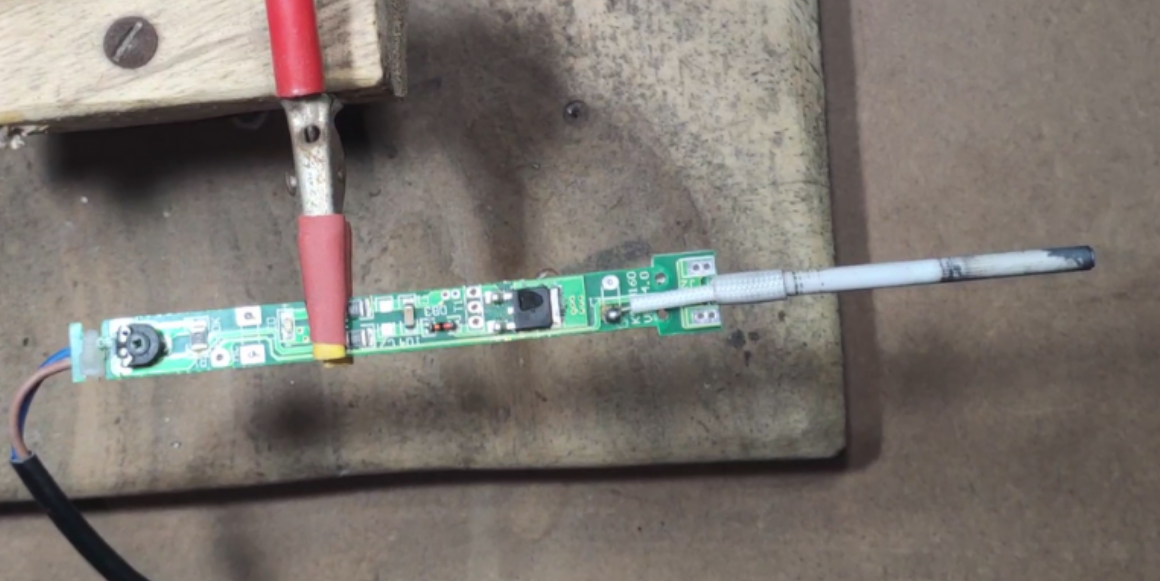

- Very carefully open the soldering iron. Don’t give extra pressure because it can break the tip.

- Inside there is a voltage regulation IC, remove that with the help of hot air gun. You can also use another soldering iron to remove the IC.

- The name of the IC will bw written on the board, usually BT136 TRIAC, buy that from any electronic market.

- Soldered the IC there and close the iron.

- Now, you can use the iron again. But still, be careful.