A Hot and Cold Water Cooler is a machine that cools or heats up and dispenses drinking water with a refrigeration unit. A water cooler/dispenser is generally used to provide easy access to cool drinkable water & is used in almost every household & workplace. Water cooling/dispensing systems are usually very expensive & come with a substantial price tag. So, In today’s tutorial, we are going to design a simple, cheap & efficient Hot and Cold Water Cooler System using a Peltier thermoelectric cooling module.

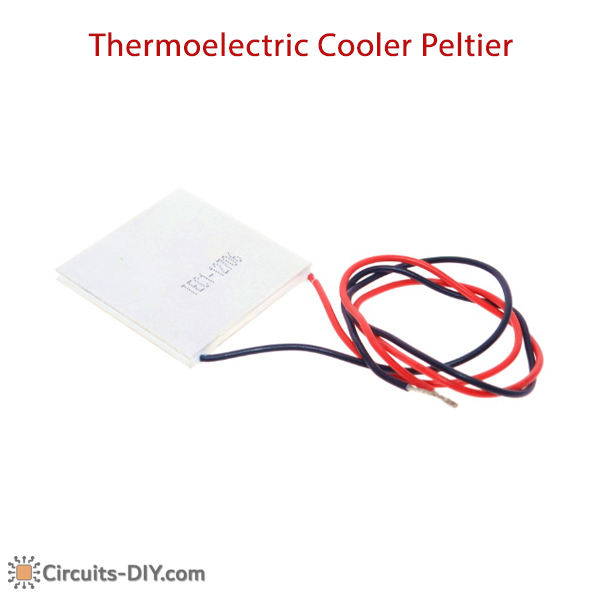

The heart of this project is a Peltier TEC module. A Peltier Thermoelectric cooling module consists of two ceramic plates separated by semiconductor pellets. One of the plates absorbs heat (cools down) and the other plate dissipates heat (heats up) when a current is passed through the pellets. It is composed of an array of ‘doped’ Bismuth Telluride semiconductor pellets so that a single kind of charge carrier, either +ve or -ve, carries the majority of the current. The pairs of P & N pellets are adjusted in such a manner that they are connected electrically in series, but thermally in parallel. The cooling/heating capability of a Peltier module always depends on the applied temperature difference between its two ceramic plates.

Hardware Component

The following components are required to make Water Cooler Circuit

| S.no | Component | Value | Qty |

|---|---|---|---|

| 1. | Peltier Module | TEC1-12706, 12V/5.8A, 60W | 1 |

| 2. | DC Submersible water pump | 12V/3M | 1 |

| 3. | PVC water tubing | 9.5mm, 1/2″ | As per need |

| 4. | Aluminum water cooling block/Heatsink | 40x40x12mm | 1 |

| 5. | Simple Heat Sink | – | 1 |

| 6. | Plastic Box with lid | Large/Medium | 1 |

| 7. | 5 min Epoxy glue | – | 1 |

| 8. | Thermal Compound Paste | Carbon-based | 1 |

| 9. | Water Spigot/Faucet | Plastic | 2 |

| 10. | Power Drill with Drill Bits | 220V | 1 |

| 11. | DC Power Supply | 12V/5A | 1 |

| 12. | AC Wall Outlet | 220V | 1 |

| 13. | Cutter | – | 1 |

| 14. | Digital thermometer with test probe | – | 1 |

| 15. | Jumper Wires | – | As per need |

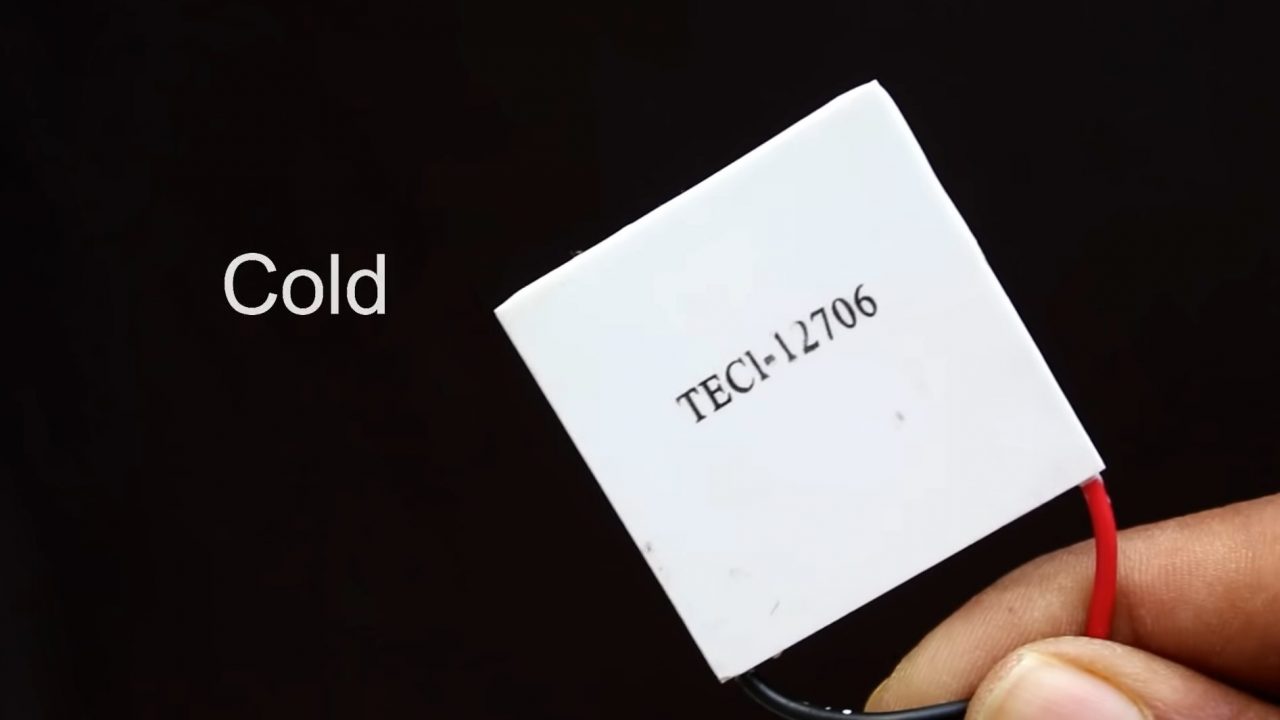

Thermoelectric Cooler Peltier Module

Aluminum Water Cooling Block

Useful Steps

Fixing the Heatsink

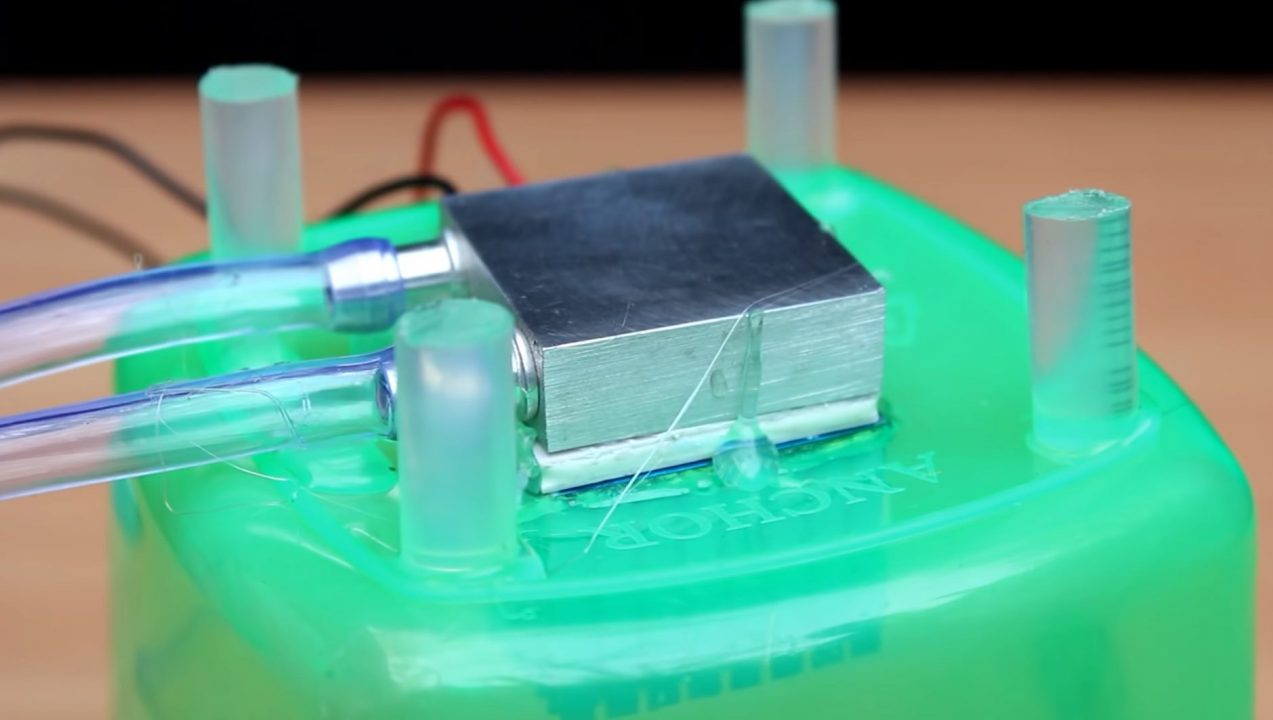

1) Cut a hole on the base of the Coldwater container with respect to the size of your heat sink. After that, fix the heat sink in the cold water container with the fin inside the container & the base at the outside of the container. Seal the base of the heat sink using 5 min epoxy glue. Cover the area around the fins using masking tape to ensure no part of the epoxy glue is leaking inside the Coldwater container.

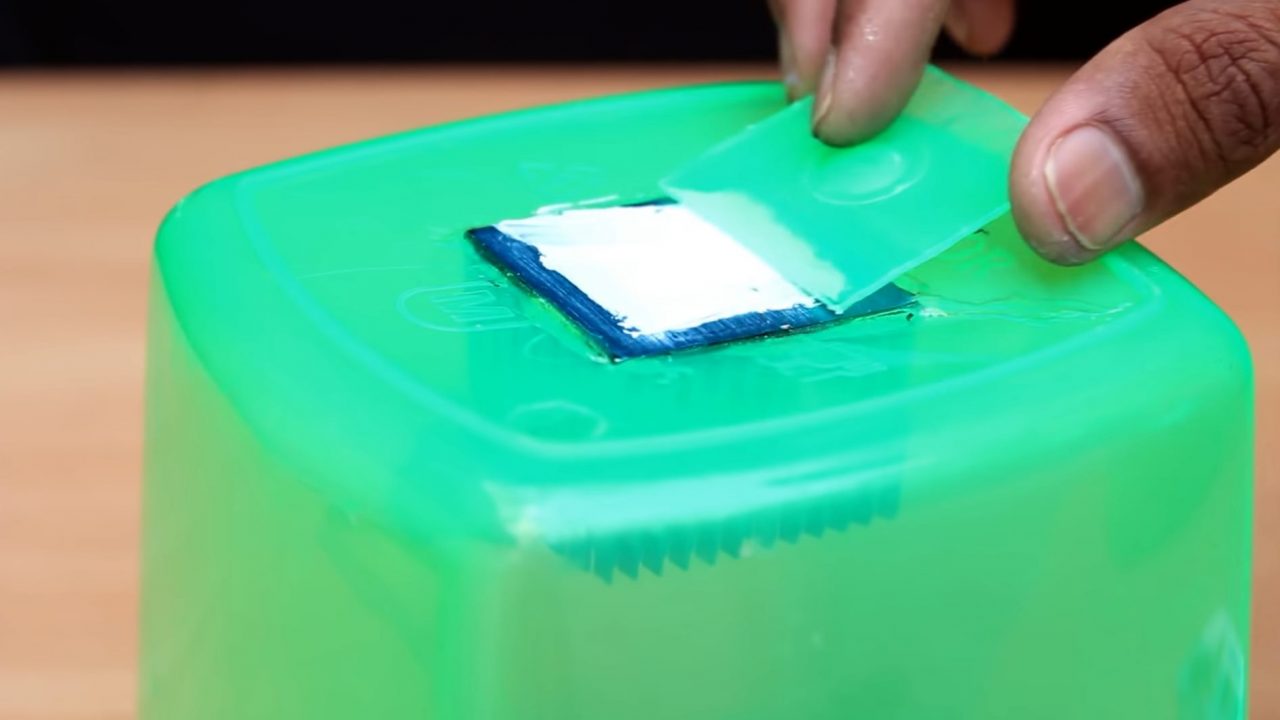

Installing the Peltier Module

2) Put a small amount of thermal compound paste on the base of the heatsink & spread it generously, so that it covers the entire base of the heatsink evenly.

3) Place the Cold side (the side with the model no.) of the Peltier module on the thermal paste. After that cover the Hot side of the Peltier module with some thermal paste.

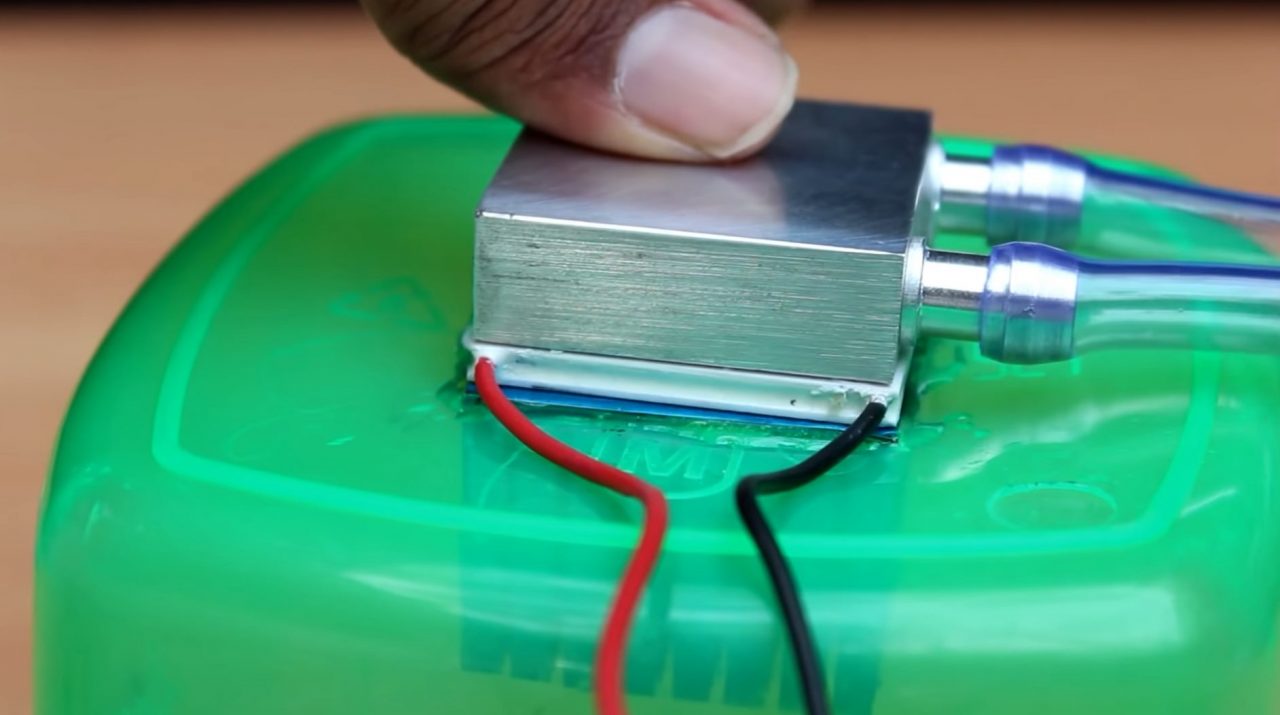

4) Put on PVC tubing on the intake & outtake valves of the aluminum water cooling block. After that, place it on the Hot side of the Peltier module covered with thermal paste.

5) Hot glue some equal-sized plastic pieces on both Hot & Cold water containers to raise the water cooling block at least 2″ from the ground. This will further help with the ventilation of the cooling block.

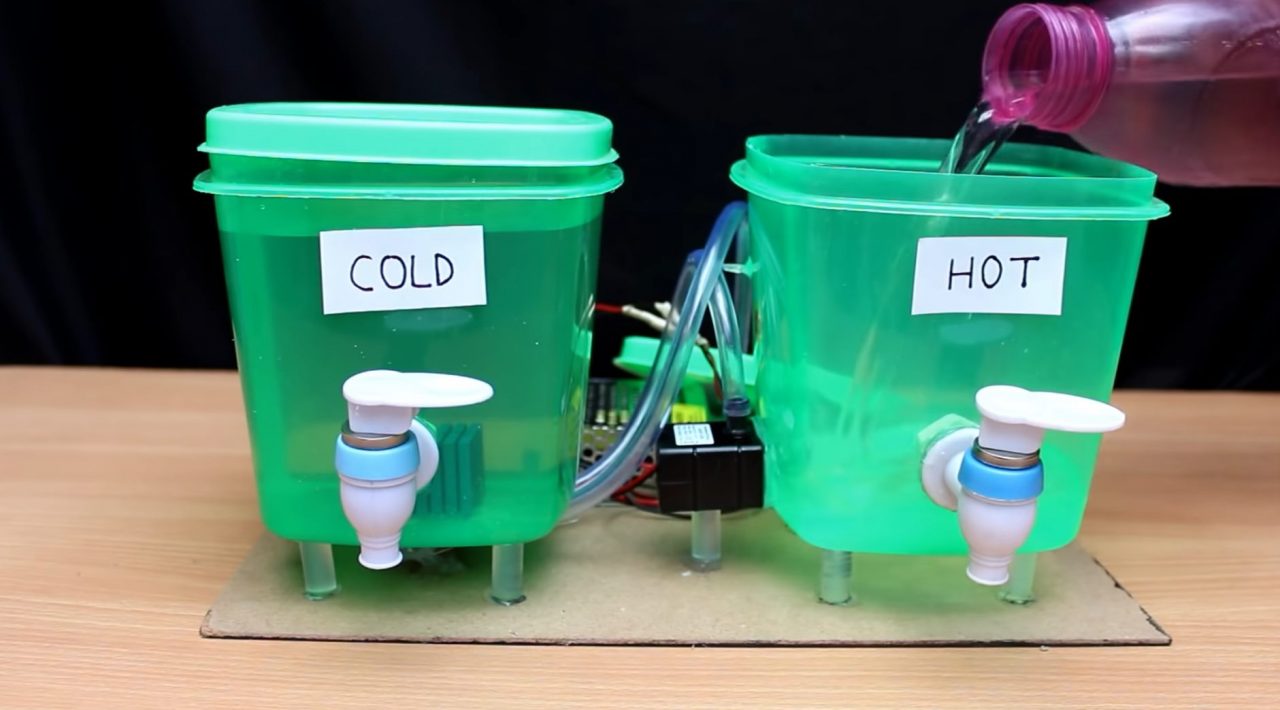

6) Fix water spigots/faucets by boring holes on the front-facing side of your water containers (Both Hot & Cold)

7) Fix the DC pump on the side of your Hot water container with the intake valve pointing inwards of the hot water container. After that, connect the PVC tubings from the aluminum water cooling block with the outtake valve of the DC pump & the hot water container.

8) Connect the Live & Neutral wire of the 220V wall Outlet with the L & N terminal of the DC power supply. After that, short both the live & GND terminals of the DC pump & the Peltier module into two separate pairs & connect them with the GND (V-) & Vcc (V+) terminal of the power supply.

9) Fill the hot & cold water containers with room temperature water. Power up & test the circuit using a temperature probe.

Working Explanation

This project works on the principle of increasing the temperature difference of the Peltier TEC module. Initially, the water in both containers is at room temperature. On powering up the 12V DC supply the water from the HOT container is pumped through DC brushless pump & is sent through the aluminum cooling block/heatsink.

The aluminum heatsink absorbs the heat from the water & gets warmer transferring the heat from the water to the heat-dissipating side (Hot ceramic plate) of the Peltier module. This causes the temperature imbalance for the Peltier module ( as the heat-dissipating side suddenly heats up) which causes the absorbing side (Cold ceramic plate) to further go down in temperature, This results in lowering the temperature of the cold water container. The temperature of the cold water container further decreases as the cycle continues & the water in the hot container gets warmer due to continuously taking in the heat of the warm aluminum cooling. You can cool down the water to as far as 16°C by running this setup for 15 minutes.

Applications

- You can use this setup to cool down water in large amounts without the need for an expensive cooling setup.