Introduction

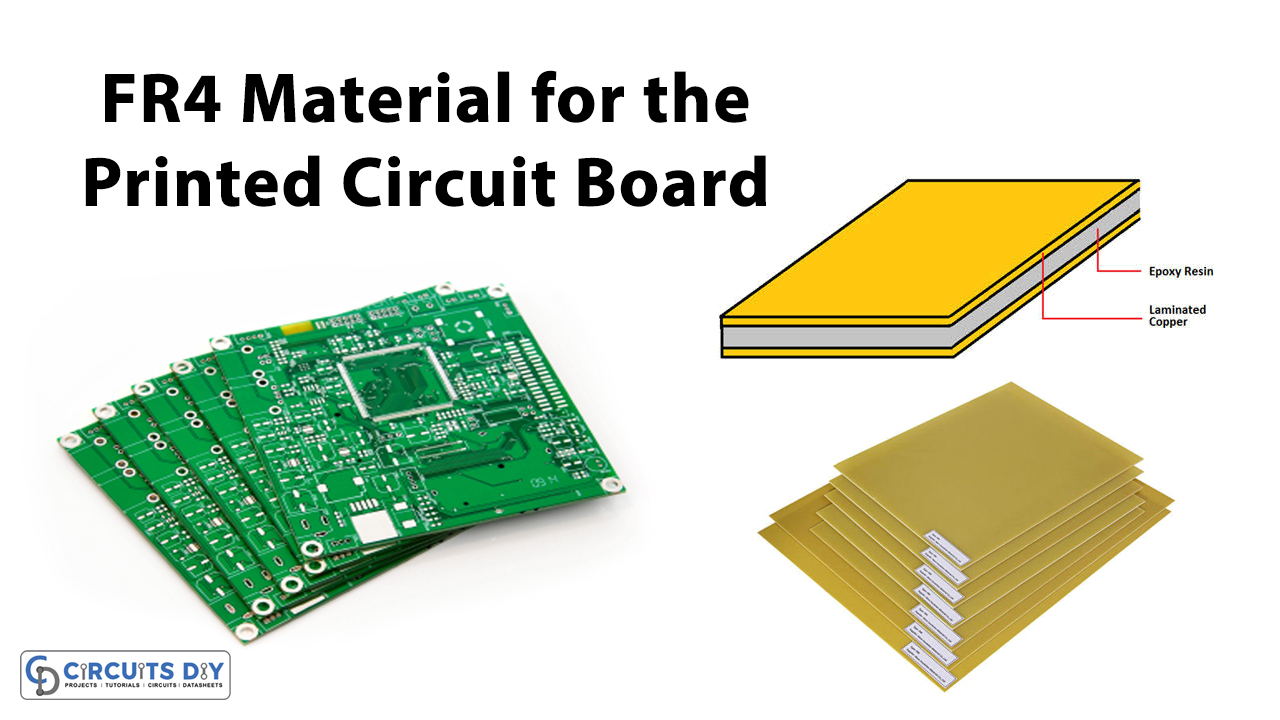

In the making and manufacturing of the printed circuit boards for electronic devices and circuits, several materials get utilized. When choosing the material, a manufacturer must have to think about the application for which the PCB is going to be employed. Hence, material plays an important role to make the devices reliable and decide the durability of the Printed circuit boards. FR4 is one of those materials that are used for this purpose. Therefore, in this article, we will discuss everything about the FR4 material for the Printed circuit board.

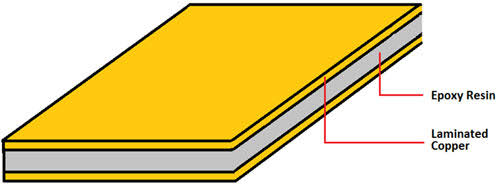

An Overview of the FR4 Material

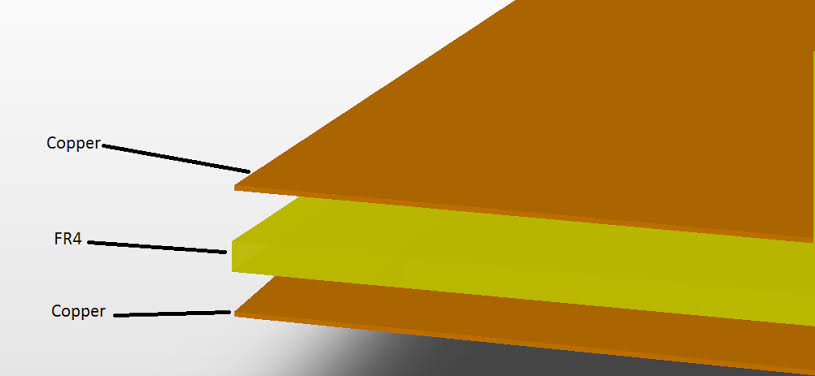

FR4, which is flame-retardant material contains the standard UL94V-0. It is a composite material for glass-reinforced epoxy. Basically, it is made up of woven fiberglass cloth having an epoxy resin binder that is primarily flame resistant. Therefore, FR4 is highly popular. Hence, it is the most commonly used insulator that has considerable mechanical strength. The FR4 is highly recommended because it retains its high electrical insulating qualities and high mechanical values

When to Use FR-4 Material

In many printed circuit boards for electronic devices and circuits, FR4 is used for greater reliability. However, the material is not ideal for every condition and application. Moreover, the material is also can not be utilized in high-frequency applications. Thus, the question here arises where should we use this FR-4 material for printed circuit boards? So, here are some answers.

- The material can be used for low-cost devices and circuits.

- Also, where mechanical and electrical stability is required.

- The Fr4 material is used in the circuits having frequencies up to 7GHz.

Where not to Use FR4 Material

As we discussed above Fr4 is not ideal for every application, especially for high frequencies the material is neither suitable nor favorable. Therefore, some important points should be noticed while choosing the material.

- FR4 has a higher dissipation factor, therefore can not be used where there is the problem of signal loss. Hence, may not be promising for wireless circuits.

- The material also should not be utilized for higher frequency and larger electronic designs. Because it is not suitable for maintaining stable impedances.

- For smaller board sizes, the design needs the material to have a greater dielectric constant. The FR4 has a lower dielectric constant.

Comparison of FR4 with High-Frequency Material

FR4 is highly used in the electronics world. A wide range of electronic devices utilized this material in their printed circuit board. But, we have discussed earlier and cannot deny that FR4 cannot be adopted for every circuit. In the passive circuit, where there may be a signal loss the material is not favorable. And, at those places, high-frequency materials are employed. Let’s compare and have a look at the difference between the high-frequency material and FR4.

- FR4 is cheaper and more affordable than the other higher-frequency laminate.

- FR4 has higher mechanical and electrical stability.

- The FR4 material has a higher Df, therefore suffers greater signal loss.

- High-frequency materials have a higher range of dielectric constant than the FR4 material.

- High-frequency materials have higher variation in temperature management than the Fr4