Introduction

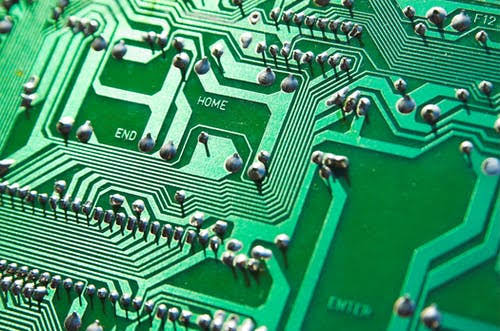

Printed circuit boards are in every device. Your computer, your laptop, and your smartphones contain the PCB. Even toys nowadays have printed boards on them. Therefore, it is necessary to look at the Factors that damage the Printed Circuit Board (PCB).

To make a better circuit and the product, a designer must need to comprehend those factors and work accordingly to reduce the probability of failure and hence the damages. So, in this article, we are going to discuss those downfalls or failures that can harm the entire board and can defect the device.

• Manufacturing Factors that damage Printed Circuit Board

One of the most important factors that damage the Printed Circuit Board and can cause failure is its manufacturing issue. Manufacturing errors are mostly because of human errors. But, still are not very common. Hence, a designer can prevent this by working on a particular manufacturing issue

- Poor Quality Boards: Firstly, Poor quality components can cause material defects, bending, and breaking. This can reduce the reliability of your device and can cause permanent damage to the specific component. Hence, good quality board elements or components may reduce this problem. If the PCB gets damaged because of the damage to particular components. Then, it can be treated by replacing the component.

- Poor Substrate Material: Further, the inappropriate substrate material can affect the electrical signals by degrading the performance. It also induces external noise.

- Misaligned Layers: Moreover, the misaligned layers usually happen because of inappropriate stack-up files. So, make sure to manage stack up the file before giving the layout for fabrication

• Environmental Factors

Certainly, some environmental factors can affect the performance of the printed circuit boards. For example, if the board is being endangered by the harsh elements, it may contribute to the failure of boards. In the same vein, some more factors like temperature, moisture, and dirt can also affect the board quality. Dirt and debris increase corrosion. Thus, decreasing the life span. Likewise, severe environmental temperature contributes to the degradation of the circuit or board.

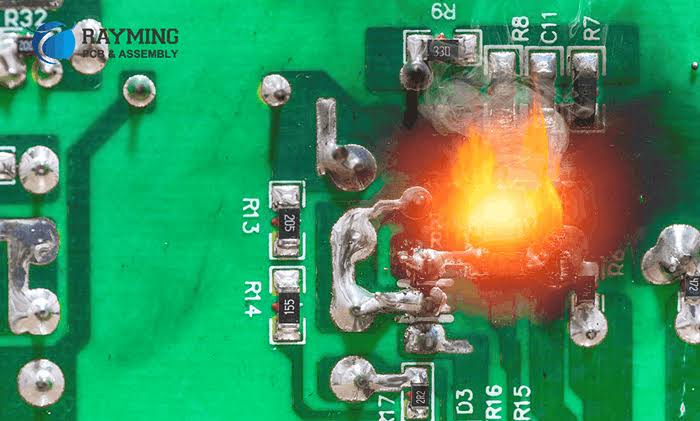

• Heat and Burnt Components

Different materials and components that are used in making the circuit have different rates of heat dissipation. So, printed circuit boards are always under thermal stress. To avoid more heat expanding in the circuits, use a thick layer of copper. And, if possible, use the heat sinks. Burnt components also cause failure and damage to the circuit. But, it may easily be overcome by replacing that particular component.

The life span of the Board

As time passes, components start failing. Inductors and capacitors may genre the power issues. Since this is an age-related problem, therefore one can reduce this issue but no one can avoid this. The designer can reduce this problem by replacing the new components. Replacing is better than assembling the new PCB. Because it is cheaper than making a new PCB.

Fixing The Factors that Damage Printed Circuit Board

Most of the damages that have been mentioned above may get fixed. But, the best way to avoid the damages from most of the factors is to prevent earlier while making. Moreover, try to fabricate your PCB with good PCB manufacturers. This may also decrease the rate of the damages