Introduction

Computer Numerical Control (CNC) machining has revolutionized the manufacturing industry by providing unparalleled precision and efficiency in creating complex parts and components. One critical aspect of CNC machining is selecting the right material for the job. The choice of material can significantly impact the final product’s quality, durability, and performance. In this article, we will delve into the various types of CNC machining materials commonly used in the industry.

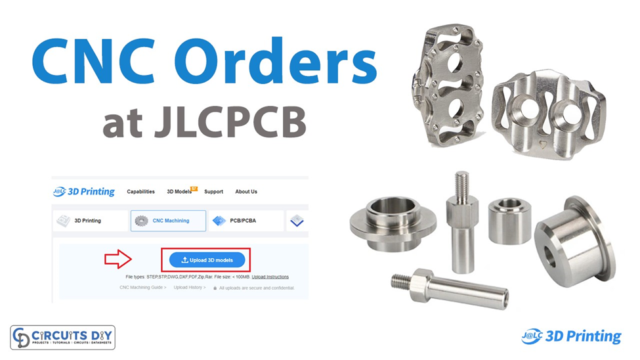

JLCPCB’s extensive range of CNC machining materials represents a gold standard in the industry. Their commitment to quality and precision is evident in the diverse selection of materials they offer, whether it’s the durability of steel for robust components, the lightweight versatility of aluminum for intricate designs, or the specialized properties of plastics, composites, and for a wide range of applications. JLCPCB’s materials not only meet the stringent demands of modern manufacturing but also cater to the ever-evolving needs of industries like aerospace, automotive, electronics, and healthcare. With their dedication to providing top-notch materials, JLCPCB ensures that engineers and manufacturers have the essential building blocks required to bring their innovative ideas to life, all while maintaining the highest standards of craftsmanship and performance.

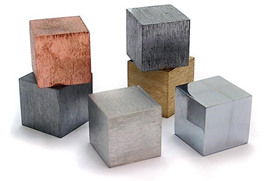

Metals

1.1 Aluminum 6061

Aluminum 6061 is a versatile material valued for its lightweight properties, excellent corrosion resistance, and machinability. It is an ideal choice for industries where low weight and exceptional strength are prerequisites, such as aerospace and automotive.

1.2 Aluminum 7075

Aluminum 7075 is another stalwart in JLCPCB’s inventory, known for its superior strength and durability. It is frequently used in applications where structural integrity and resistance to wear and tear are paramount.

Copper and Brass

2.1 Copper – H59

Copper H59 is a high-quality copper alloy, prized for its electrical conductivity and corrosion resistance. It finds applications in electrical components, heat exchangers, and plumbing.

2.2 Copper – T2

Copper T2, another copper variant, is celebrated for its thermal and electrical conductivity. It’s often used in electrical wiring, connectors, and heat transfer solutions.

Plastics

3.1 ABS (Acrylonitrile Butadiene Styrene)

ABS is a versatile and impact-resistant plastic used in a wide range of applications, from consumer products to automotive components.

3.2 FR4 (Fiberglass-Reinforced Epoxy)

FR4 is a flame-retardant composite known for its excellent electrical insulating properties, making it ideal for printed circuit boards (PCBs).

3.3 Nylon-PA6

Nylon-PA6 is celebrated for its exceptional tensile strength and wear resistance, often used in the manufacturing of gears, bearings, and structural components.

3.4 Polycarbonate

Polycarbonate is a robust and impact-resistant plastic frequently employed in the production of bulletproof windows, eyewear lenses, and automotive components.

3.5 PMMA (Polymethyl Methacrylate)

PMMA is a transparent plastic lauded for its optical clarity and ease of machining. It is widely used in applications such as signage, lighting fixtures, and medical devices.

3.6 POM (Polyoxymethylene)

POM is a high-performance engineering plastic recognized for its low friction and excellent mechanical properties, often found in the manufacture of precision parts and gears.

3.7 Polypropylene

Polypropylene is a lightweight and chemically resistant plastic used extensively in food packaging, medical devices, and various consumer goods.

3.8 Bakelite

Bakelite, an early synthetic plastic, boasts excellent electrical insulating properties. It is employed in various electrical and electronic components.

Conclusion

JLCPCB’s vast array of CNC machining materials offers a diverse set of options to cater to the complex and evolving needs of modern manufacturing. Whether you require the strength and lightweight properties of aluminum, the conductivity of copper and brass, or the versatility and resilience of plastics, JLCPCB ensures that the materials you need are readily available. Their dedication to providing top-notch materials, combined with an unwavering commitment to precision and quality, ensures that engineers and manufacturers can bring their innovative ideas to life across a broad spectrum of industries.