Introduction:

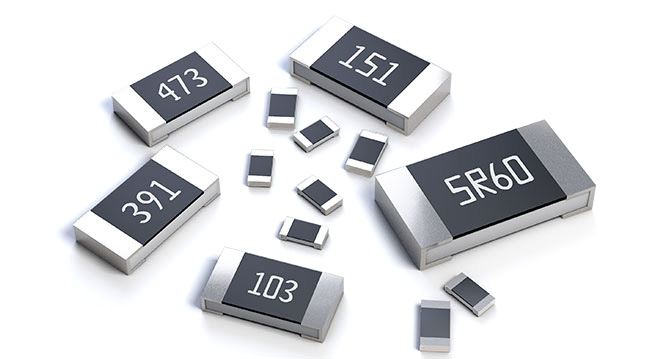

Resistors are fundamental electronic components used to limit the flow of electric current in a circuit. They are crucial in shaping the behavior of electrical devices and ensuring their safe and efficient operation. In this article, we will explore the various types of resistors available in the market and delve into their specific applications.

Types of Resistors and Applications

There are several types of resistors here we will discuss important ones depending on applications & uses.

Carbon Composition Resistors:

Carbon composition resistors are one of the earliest types and consist of a solid cylindrical resistive element made from a mixture of carbon particles and a binding material. These resistors offer moderate accuracy and are typically used in low-cost applications such as power supplies and audio circuits. However, their use has diminished due to advancements in resistor technology.

Metal Film Resistors:

Metal film resistors are constructed by depositing a thin layer of metal alloys, such as nickel-chromium or tin-oxide, onto a ceramic substrate. This results in a highly stable and precise resistor with better temperature coefficients compared to carbon composition resistors. Metal film resistors find applications in precision electronic circuits, audio equipment, and signal processing.

Metal Oxide Film Resistors:

Metal oxide film resistors are similar to metal film resistors but employ metal oxides instead of metal alloys. These resistors offer superior stability, higher power handling capabilities, and low noise characteristics. They are commonly used in power supplies, industrial equipment, and automotive electronics.

Wirewound Resistors:

Wirewound resistors consist of a metallic wire wound around an insulating core, resulting in high power handling capabilities and excellent temperature stability. They are often used in power electronics, motor drives, and high-frequency applications where precision and durability are paramount.

Thick Film Resistors:

Thick film resistors are fabricated by screen-printing a resistive paste onto a ceramic substrate and then firing it at high temperatures. These resistors are cost-effective and widely used in consumer electronics, automotive applications, and telecommunications equipment.

Thin Film Resistors:

Thin film resistors are made by depositing a very thin layer of resistive material onto a substrate through techniques like sputtering or evaporation. They offer exceptional stability, accuracy, and low noise, making them ideal for high-frequency and precision applications like medical instruments and aerospace electronics.

Variable Resistors:

Variable resistors, also known as potentiometers or trimmers, allow users to adjust resistance manually. These resistors are commonly found in volume controls, tuning circuits, and calibration applications.

Applications:

- Carbon composition resistors: Low-cost electronics, audio circuits, and hobbyist projects.

- Metal film resistors: Precision electronics, amplifiers, and instrumentation.

- Metal oxide film resistors: Power supplies, industrial equipment, and automotive electronics.

- Wirewound resistors: Power electronics, motor drives, and high-frequency applications.

- Thick film resistors: Consumer electronics, automotive electronics, and telecommunications equipment.

- Thin film resistors: High-frequency applications, medical instruments, and aerospace electronics.

- Variable resistors: Volume controls, tuning circuits, and calibration applications.

Conclusion:

Resistors are essential components in electronic circuits, and choosing the right type can significantly impact the performance and reliability of your designs. Whether it’s precision, power handling, or cost-effectiveness, there is a resistor type tailored to suit every application. Understanding the characteristics and applications of different resistor types empowers electronic engineers and hobbyists to create optimized and efficient circuits for various purposes.