Introduction

To make any product, design, or circuit, the main aspects are the quality and the price. Low quality with low prices is not favorable. Similarly, high quality with high prices is not affordable. Thus, the main goal of every designer is to make a device having high quality at affordable prices. This can be done by a few yet important tips which we will discuss in this article. Hence, this article is about the cost-saving tips for PCB Fabrication.

Keys to Reduce the PCB Fabrication Cost

No one wants to pay more or to buy a product having very high prices. So there are some keys or tips that can help a designer to reduce the board’s cost.

- Small Board size

- Low cost, high-quality material

- fewer vias

- Large Batches

- Penalization

Small Board Sizes

The larger the board size, the higher will be the cost. The Larger board size means it requires more components. Also, the shipping price may get increased as the size increases. Printed circuit boards can be originated with the dimensions of 500mm*110mm. But, this may cost very higher. The promising size with an affordable price would be 100mm*100.

Low Cost, High-Quality Material

Materials like aluminum, polyamide, and ceramic are relatively expensive and can cost more. So, the most commonly used material for a better price is the FR4 laminated fiberglass. Moreover, fiberglass comes with different grades concerning temperature and resistance. Hence, the commonly adopted grade for low prices is TG130-140.

Less Vias

Vias create more complexity in the circuits. Certainly, through-hole vias are more cost-effective than laser or buried vias. Also, the hole size of vias plays an influential role. The smaller sizes require more miniature tools for drilling. Thus, the cost would be higher. Also, smaller drills break quickly and make the board unreliable.

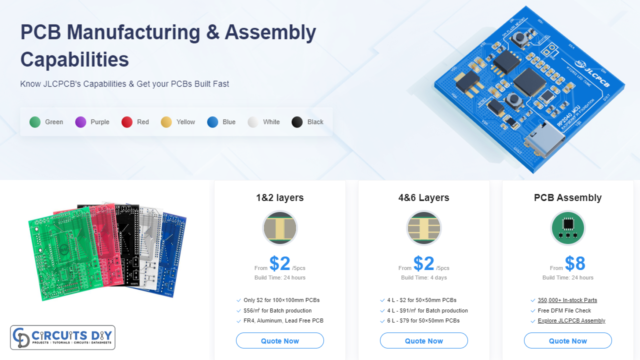

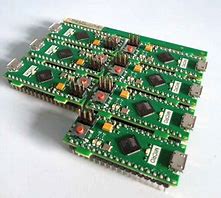

Large Batches

It is an economical practice that if you want to decrease the price then increase the quantity or the volume of the product. The greater the quantity, the lower would be the manufacturing price. For example, 3 units of 2 layers would cost more than the total cost of 10 units of 2 layered PCBs. Furthermore, It is also favorable for shipping. Large batches of PCBs would cost low shipping prices. Hence, with the fabrication cost, it is also reducing the shipping cost.

Panelization

Where panelization helps to generate faster and more beneficial products, it also helps to decrease the prices. Most importantly, it only wastes very few components or elements. Hence, it just not only saves the cost but also improves the fabrication lead time.

Conclusion

In the above-described subject, we have seen the fundamental essential tips and points Cost-saving tips for PCB that can maintain the price of the printed circuit boards. But, they are not the only cost-effective tips. There may be a bunch of further tips than the above-mentioned. Hence, we tried to highlight the most obvious and easiest methods to defeat the higher costs. To sum up, if you work on these suggestions, that may definitely help you to build a reliable, and affordable printed circuit board.