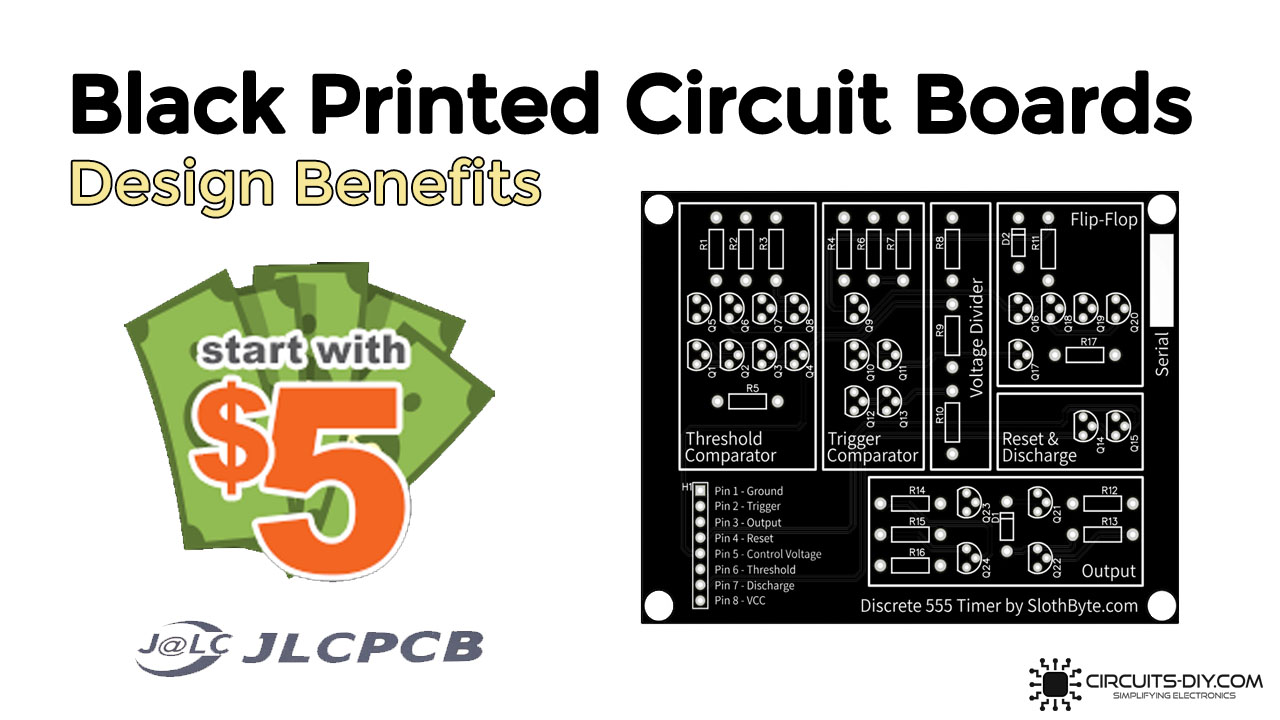

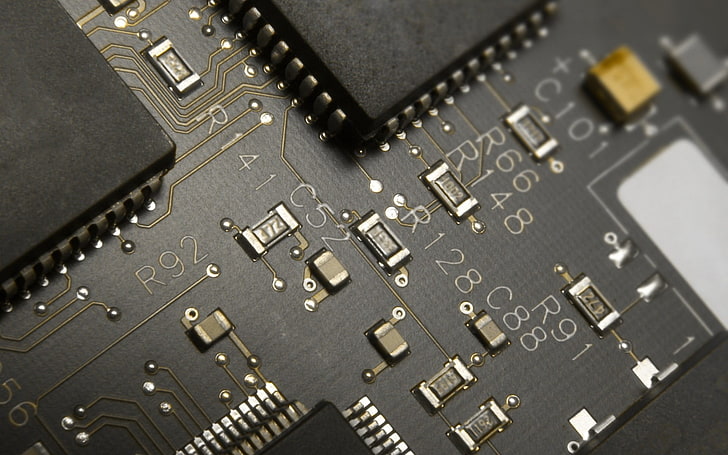

We are experiencing rapid development in the field of DIY electronics and its direct implications on the Printed circuit board industry. As a result, the rapid development of the DIY electronics industry has expanded the market of the printed circuit board industry. Recent market surveys indicate that there has been an increasing trend in people agreeing with the fact that the final color, mainly the color black speaks for the overall quality of the PCB itself. This interest has also been found true in many big name companies such as MSI, Apple, and Asus that mainly utilize black PCBs for their motherboards and device internals. But does the color of the PCB board really dictates its design and operational metrics?. In today’s article, we will focus on discussing what is a Black printed circuit board, its design benefits and its limitations.

Black Printed Circuit Board?

A black printed circuit board is similar to any other printed circuit board with the key difference in its appearance. The black color of the PCB is achieved when the solder mask is still in the molten state. The PCB design and manufacturing process is exactly the same for the black PCB as it is for other PCBs, as the color will not have any impact on the performance of the PCB.

JLCPCB is the foremost PCB prototype & manufacturing company in china, providing us with the best service we have ever experienced regarding (Quality, Price Service & Time).

Design Benefits Of Using Black Printed Circuit Boards

1) Low Light Reflectivity

One inherent advantage of using a black Printed Circuit Board is that they are appropriate in circuits where the reflection of light is not required. Such circuits would need the use of a black PCB to function properly and effectively.

2) Versatile

Black PCBs are versatile enough to be covered with different coatings depending on your needs. Here, It is vital to consider properties such as chemical resistance, mechanical resistance, moisture resistance among other factors that make the PCB suitable for use effectively.

3) Visually Appealing

The name of black PCBs is still synonymous with luxury. Big name brands thrive on this feature and connect themselves with their properties as much as possible.

4) Great For Promoting Anti – Plagiarism

Black PCBs are great for preventing design thefts through plagiarism since the copper traces on a black PCB are difficult to figure out with the naked eye. It is very difficult to pirate a black PCB by just following the design traces present on the board.

Limitations of Black PCBs

1) Low Surface Resolution

The trace paths on a black PCB are difficult to visualize without a decent light source. Due to the low resolution of the routing paths themselves. It becomes increasingly hard for designers and manufacturers to work on the board.

2) Susceptible to Rough housing

Black PCBs are inherently incapable of handling scratches and bumps. Any small scratch or bump can result in undesirable blemishes on the surface of the PCB. At first, the blemishes may not look like much. But once the PCBs are transported and stored, they’ll start to look ugly as the stains age.

3) Slight Toxicity of Black Ink

Using Black inks in PCB manufacturing tends to be a little bit more toxic. Although black inks are way more expensive than green inks, their chemical composition makes it more toxic. Also, For PCB manufacturers, wastewater treatment becomes more troublesome.