Introduction

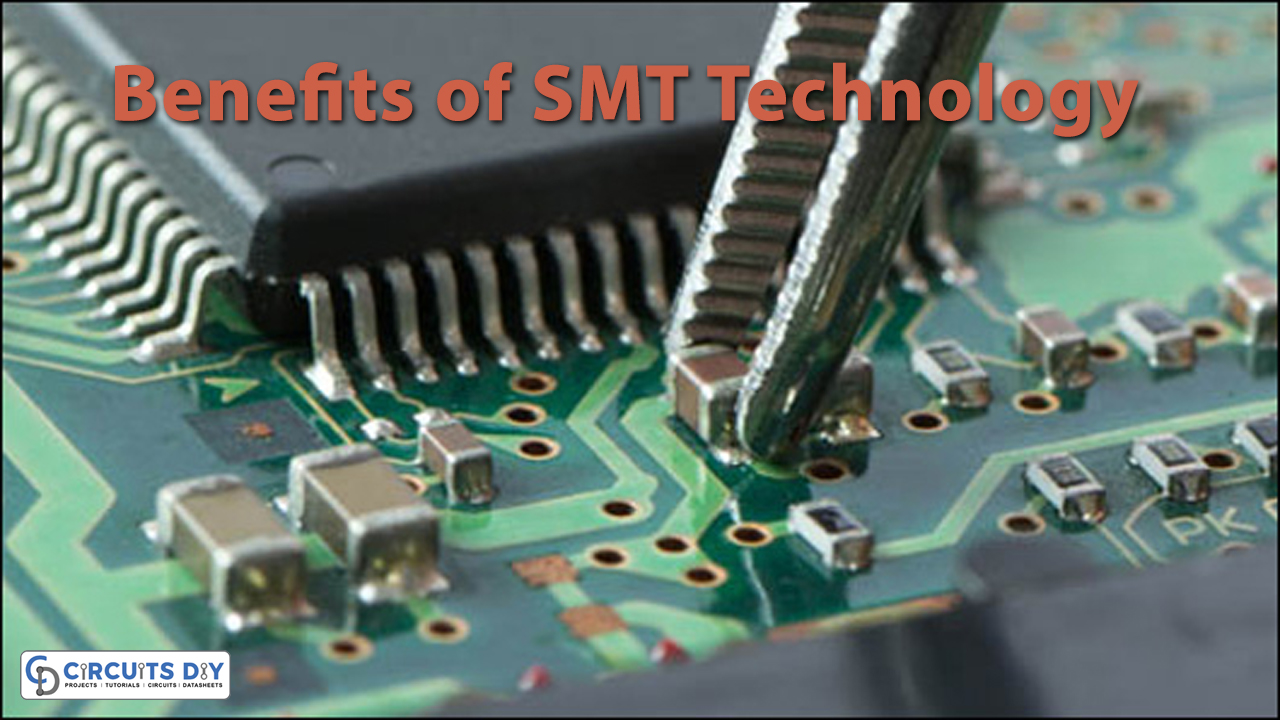

With the ongoing shrinking of consumer electronics, it has become obvious throughout the years that a new category of components is needed in the present design industry to support the growing trend in technological size reduction. Surface mount technology, or SMT, has prepared the way for SMT to take over the present PCB market. In today’s post, we’ll look at what SMT PCB technology is and what its design advantages and limits are. In this article we will discuss the Benefits of SMT Technology, and why should we utilize JLCPCB SMT technology.

Brief introduction of SMT Technology

Surface-mount technology (SMT) is a printed circuit board component assembly method in which components are affixed and linked on the board’s surface utilizing the solder-reflow process. In other PWB processes, component leads are put into plated through-holes and soldered from the bottom to join the components. Compared to the through-hole insertion technique, SMT provides the advantages of increased package densities, improved reliability, and lower cost. SMT is now the most popular method for producing low-cost, high-volume consumer electronic assemblies.

Components Used in SMT Technology

SMT is made up of three primary component categories, which are listed below:

- Resistors and capacitors are the most typical examples of passive components. They do, however, have coils. These are for gadgets that demand a large quantity of electricity.

- Transistors and diodes are very tiny components. Transistors also have three legs, making them simple to solder.

- Several types of integrated circuits. Some have eight pins, some have fourteen, still others have more, and microprocessors might have 200 pins or more. SMT has decreased the size while maintaining all of the features and power that they are entitled to.

Benefits of SMT Technology

The surface mount technique has been the industry standard for PCB fabrication over the last few decades due to its numerous advantages and benefits. Let’s have a look at some of the most significant advantages it can provide.

Small Sizes and lightweight

Surface-mount technology (SMT) allows components to be positioned closer together on the board, resulting in smaller PCB designs. As a result, devices may be built to be lighter and more compact. This means that the boards’ weight will be reduced. Designers have considerably more options thanks to the reduced weight. Devices that have smaller and lighter boards, for example, will weigh less and consume less power. In rare circumstances, reducing the weight of things might help lower delivery expenses. Lightweight is preferable, and SMT may excel in this area as well.

Higher Density of Electronic Components

SMT allows you to put more components onto your PCB. You can add extra components per unit of the area since there are no gaps. Additional connections per component can also be added. Components can be inserted on both sides of the circuit board since holes do not obstruct routing space on the inner or back-side layers. This can decrease the requirement for multi-layer boards in some cases.

Low Cost

Smaller SMDs or components are less expensive than their bigger through-hole counterparts. Of course, the manufacturer you pick to manufacture the boards will have an impact on how much they cost. Thus, JLCPCB provides SMT technology services at very affordable prices.

Easy Assembly

Because these boards don’t have any through-holes to contend with, they’re easy to put together. Faster assembly for the manufacturer is often the result of simpler assembly for the manufacturer. Thus, manufacturers like JLCPCB makes it easier. This means you’ll get your boards faster. It also decreases the chance of making a mistake during the assembling procedure.

Conclusion

SMT is a PCB component assembly technique that uses a batch solder-reflow method to connect and attach components to the board’s surface. The SMT process produces an SMT PCB, which is a great replacement for previous through-hole PCB production and design methods. It has triumphed in situations where weight, size, and automation are important factors, allowing it to build printed circuit boards quickly and without sacrificing quality or dependability. Hence, companies like JLCPCB making it more convenient, affordable, and better.