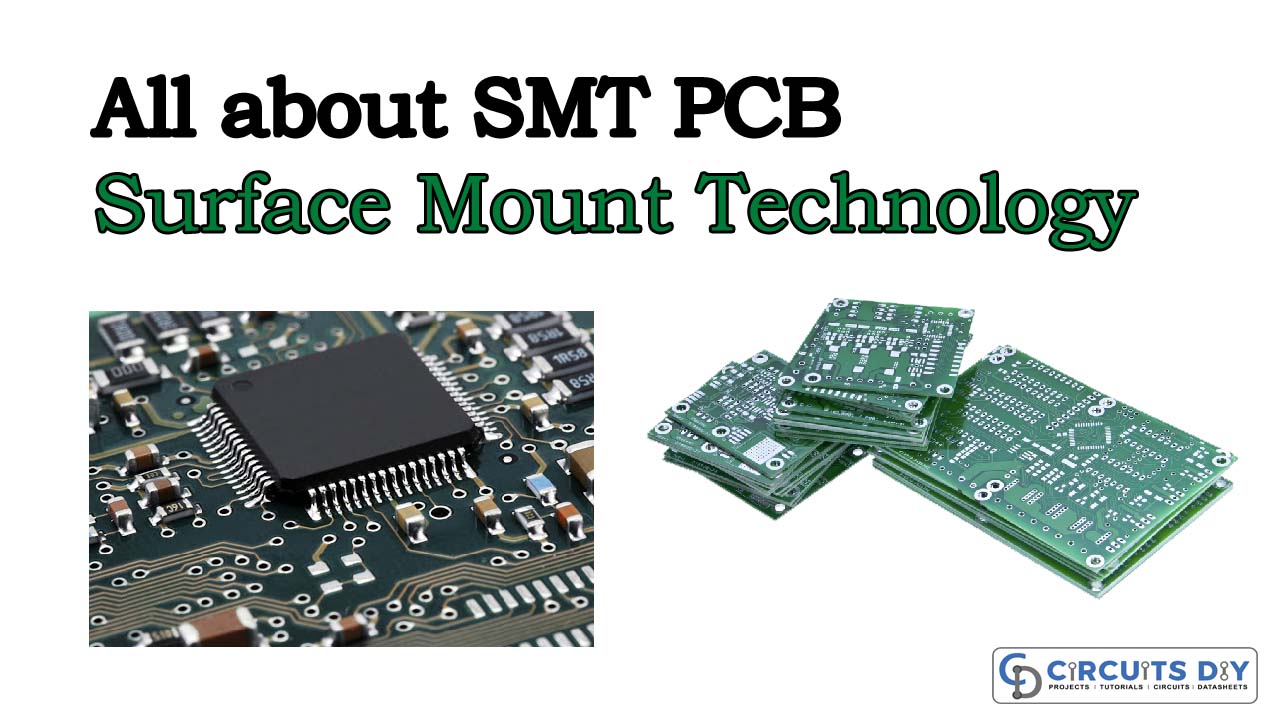

Introduction

SMT, which is the surface mount technology of the printed circuit boards is the technique. In this method, the components are mounted directly on the surface of the PCB. However, it increases the risk of errors because of the denser packing of the PCB board. The SMT has usually smaller components. It has small leads or no leads at all.

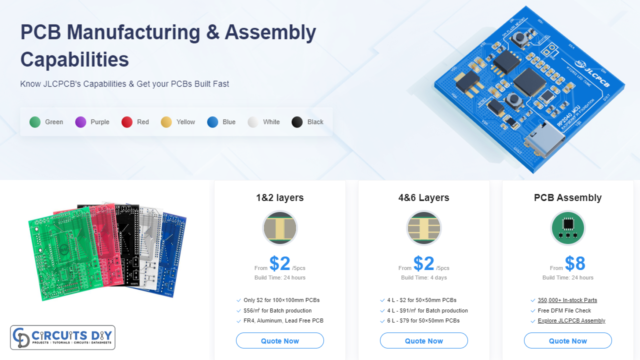

JLCPCB is the foremost PCB prototype & manufacturing company in china, providing us with the best service we have ever experienced regarding (Quality, Price Service & Time).

History of SMT

Printed circuit boards started growing in the 1970s and 1980s. At that time, all PCBs were built by through-hole technology. Later, it was discovered this THT can be problematic to creating the boards. And, It may not work properly in the future. To eradicate those problems surface mount technology got introduced. Now, instead of wires or leads, components can be soldered on the board. As a result, devices or circuits have got far better from the past.

Components of SMT

SMT has three main components that are described below:

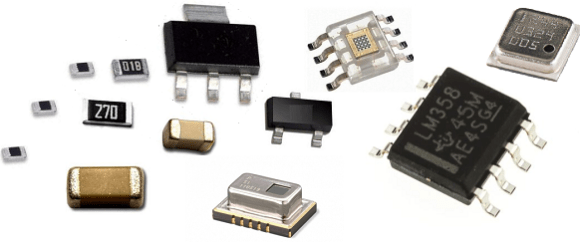

- Passive components: The most common examples of this are the resistors and the capacitor. However, they also contain coils. These are for the devices that require a significant amount of power

- Transistors and Diodes: These are very small. Also, transistors have three legs, which makes them easy to solder.

- Integrated Circuits: Integrated circuits are of different kinds. Some have 8 pins, some of having 14 pins, some have more than that, and some that have microprocessors can have 200 pins or more. SMT has reduced the size while giving them all the features and power that belongs to them

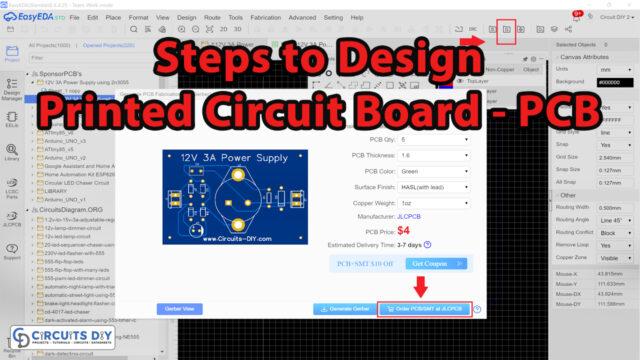

Manufacturing Methods

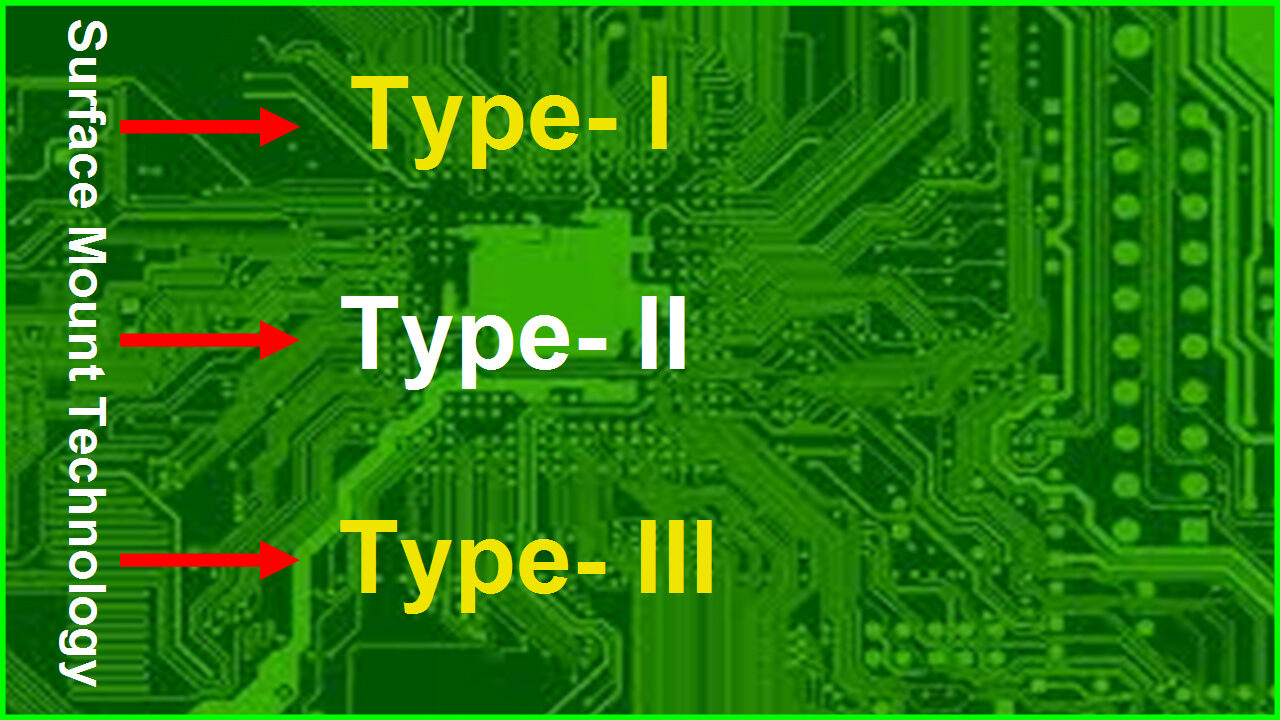

There are two methods or techniques of surface mount technology

- Type 1A and 1B Assembly

- Type 2 Assembly

1A Assembly

In this, surface mount components are only soldered on the component side of the printed circuit board. The steps include the paste application, placement, Preheating, and then cleaning.

Type 1B Assembly

In this type, components can be connected on either side of the boards. An adhesive application is needed after the paste is applied on the secondary side. However, it can be avoided by using low melting point solder on the other side of the board.

Type 2 Assembly

On this primary side have both through-hole and surface mount components are attached. But, the secondary side has only surface-mount elements. Since it is the assembly of mixed components. Therefore, it includes more operations and time.

Advantages of SMT

- It has a high assembly density, leading electronic devices to less weight

- It has high vibration resistance

- SMT ignore reliable

- Having Less error of soldering point

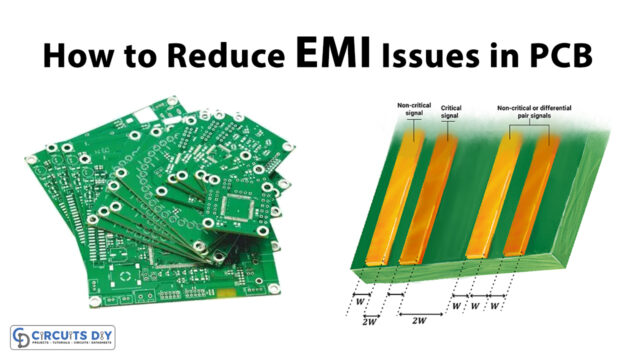

- SMT has a high frequency that reduces electromagnetic and RF reduction

- It saves the cost of the device

Conclusion

SMT assembly is more reliable and efficient. Yet, it requires knowledge of the whole process. Also, it has certain demands for the design phase. SMT makes productive and effective designs. It can assemble more components in a smaller place. As a result, it saves money and reduces error But, still it’s growing day by day. We are expecting it to improve more in the future. However, it is necessary to manufacture it properly with experienced designers and great equipment.