Introduction

As we all are aware that printed circuit boards are the mechanical help for the electrical components and wiring. Hence, it requires different manufacturing or fabrication methods. However, all the methods use some kinds of inks in the fabrication process. Thus, the Printed circuit boards require conductive inks that must contain conductive material like copper, gold, or silver. So, in this article, we will discuss Printed Circuit Board (PCB) inks.

Types of PCB Inks

Generally, Printed circuit boards inks are divided into three types. And, they are:

- Etching Ink

- Solder mask Ink

- Text Ink

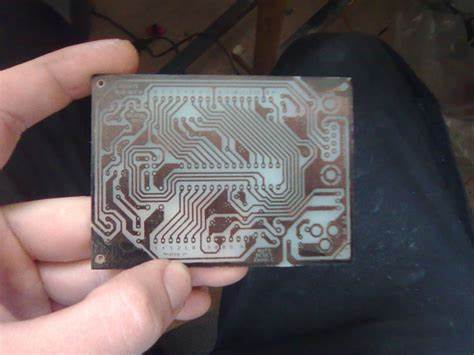

Etching Ink

The substrate that is used in the fabrication of the printed circuit board has a copper clad with a layer of copper foil. It requires screen printing which is done with photo-sensitive etching ink. This etching ink is applied for protection. And, hence it gets removed after the line has been etched. The removal of the ink can be done by the aqueous solution of sodium hydroxide. Mostly, the color of the etching inks is blue and that’s why known as photosensitive blue oil. This is also popular as photosensitive glue. However, there is an immense difference between this ink and the photosensitive inks that are used for the plate.

Solder Mask Ink

The green paint that you see on the printed circuit boards is actually the solder mask inks. Moreover, solder mask inks include:

- Photosensitive developing inks: This ink has high requirements. And, after the screen plating, this necessitates being exposed. Generally, photosensitive developing inks are utilized to make various printed circuit hard boards. The link is also adopted on the circuit boards with precision pads on the soft boards.

- Ultraviolet Ink: Ultraviolet inks are generally cured by ultraviolet light. For the large volume automated circuits, or for the circuits that are not very demanding, ultraviolet ink of green oil is highly get utilized. Practically UV inks have poor adhesion.

- Thermosetting inks: They are kept thermally and exposed directly after printing.

Text PCB Inks

The values or variables that you see on the printed circuit boards are usually written by the text inks. They are generally exposed to the color white or black. However, white inks are used more often than black ones. But, some manufacturers are also utilized yellow ink as per the needs of the customers. However, ink manufacturers are not more willing to produce this color, as the usage amount of this ink is pretty much very inadequate.

Conclusion

In the above-mentioned headings, we have seen different types of inks that are used in the fabrication process. Every link that we have studied has its own functionality and uses. Moreover, the three types of inks are not comparable with each other, as they all have different purposes. The etching ink applies for the protection of copper on the PCB. A solder mask ink plays a crucial role to make a protective effect. Therefore, used as the insulator that protects copper foil. The text ink is simple and has the only function to display the written text. Mainly, adopted to make graphics or characters.