Introduction

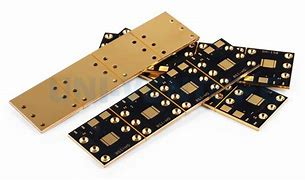

As we all know, printed circuit boards are vital components of portable electronic devices or gadgets. Thus, printed circuit boards do have a base that is the major element of the circuit. As a result, the substrate is employed as the base in PCB. However, such substrate is inefficient in terms of thermal efficiency. So, the metal core PCB is available to suit the demands of high thermal goods. The metal-core printed circuit board is abbreviated as MCPCB. It is also known as a thermal PCB. It is made of metal as its foundation. This material, which is commonly copper or aluminum, is applied to one side of the PCB. Here in this article, we will discuss the Top 5 Advantages of Metal Core PCBs

JLCPCB is the foremost PCB prototype & manufacturing company in china, providing us with the best service we have ever experienced regarding (Quality, Price Service & Time).

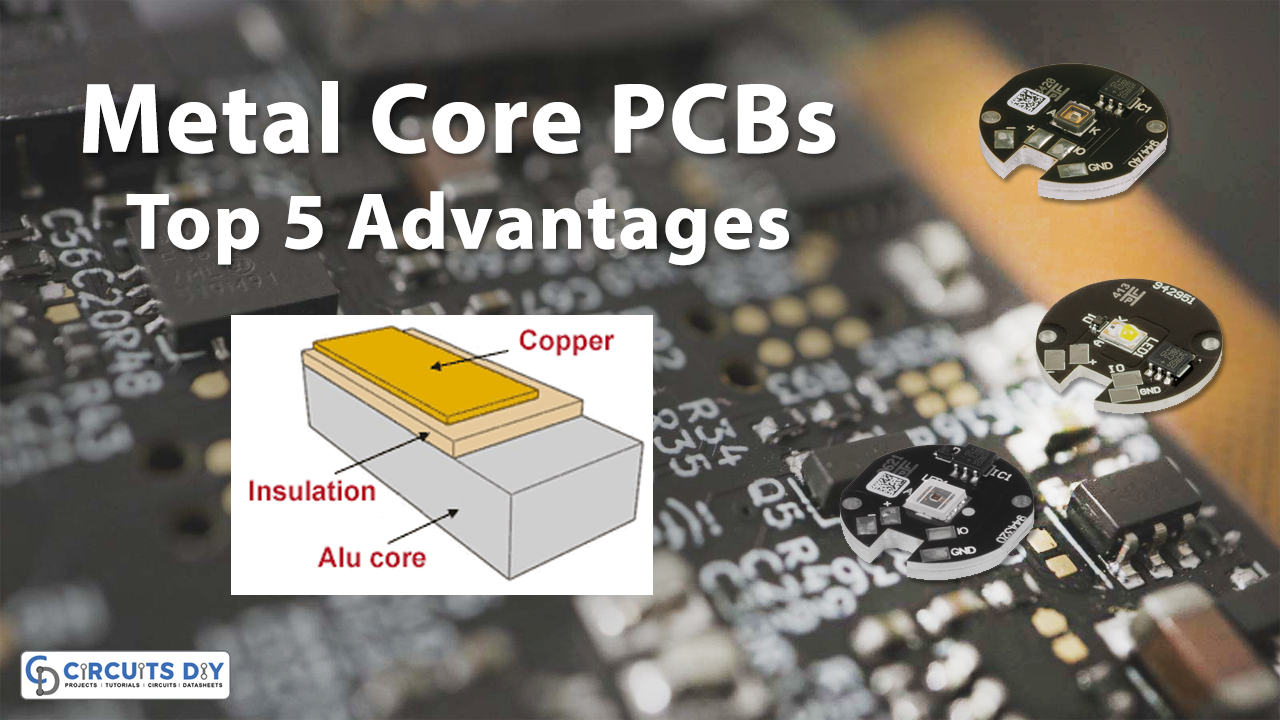

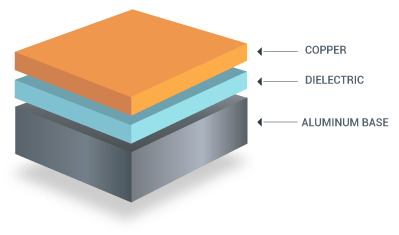

Layers in Metal Core PCB

Metal PCBs are made up of three layers:

- A dielectric layer with high thermal conductivity and hence high dissipation

- A metal layer. Aluminum, and copper are the most often used materials for metal layer manufacturing, however, stainless steel can also be utilized in specific situations. The metal layer might be wholly made of metal or a mix of fiberglass (FR-4) and metal. Metallic printed circuit boards can then be single-sided or double-sided, with the multilayer form being less prevalent due to its high manufacturing complexity.

- A copper film with high heat dissipation capacity and mechanical strength is used for circuit lithography.

Structure of Metal Core PCB

The top layer is made up of a thin copper sheet on which traces will be engraved, just like on traditional printed circuit boards. This layer’s thickness is typically between 1oz to 4oz, although it can be thicker. The dielectric substance serves as the innermost layer, electrically isolating the metal layer from the copper film while permitting quick heat transmission between the two levels. Finally, there is the metal layer, which is typically constructed of aluminum and has a thickness ranging from 1mm to 3.2mm.

Top 5 Advantages of Metal Core PCBs

Here are the Top 5 Advantages of Metal Core PCBs :

High Thermal Conductivity

When compared to other FR4 PCBs, the thermal conductivity or proficiency of MCPCB is quite high. The FR4 PC material is inefficient at transmitting heat. On the other hand, this PCB metal has strong conductivity, which aids in the protection of the layer and the components.

Dimensional Stability

The metal core provides higher dimensional stability. It shrinks by at least 2.5 to 3 percent when heated between 30 and 150 degrees.

Less Distortion

Because of its high heat conductivity. As a result, there is less distortion in the circuit. This characteristic is thought to be beneficial for high-switching power applications. This implies that it solves the problems caused by thermal expansion and contraction. As a result, the gadget with a metal core has a high durability rate.

Lighter Weight and low Cost

Aluminum boards are lower in weight than ceramics. Aluminum is relatively easy to mine and produce, making it significantly less expensive than other metals. As a result, the production costs for PCBs with aluminum substrates can be decreased. Aluminum PCBs are also a less costly and bulkier alternative to more expensive and large heat sinks.

Longer Life Span

Aluminum is stronger and more durable than other materials often used in PCB construction, such as ceramic and fiberglass. It is an extremely strong metal that can reduce the danger of unintentional breaking throughout the various phases of manufacture, assembly, or routine usage of the final product.