Introduction

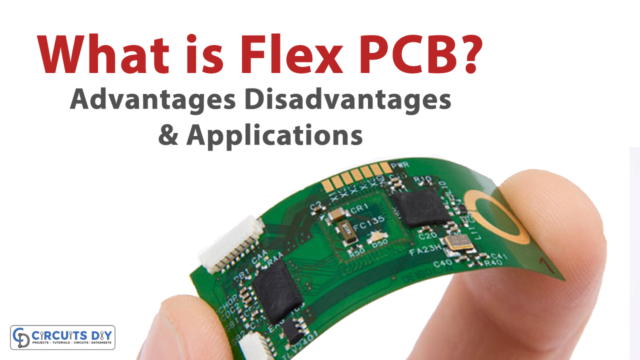

Any part of manufactured electronic equipment nowadays days is packed with tiny electronics. Rather than utilizing standard components with wire leads, these components are attached directly to the boards’ surfaces, and many are quite small.

Surface Mount Technology, SMT, is a term used to describe this technology. Surface mount technology, or SMT, is now used in all commercially manufactured electronics since it provides substantial advantages during PCB manufacturing and allows significantly more electronics to be placed into a much smaller space due to the reduced size of SMT components.

Aside from the size, surface mount technology enables automated Printed circuit board assembly and soldering, resulting in considerable gains in dependability as well as significant cost reductions.

JLCPCB Offering 2$ PCB Prototype for all SMT and Through Hole Boards

Advantages of SMT

- It has a high assembly density, leading electronic devices to less weight

- It has high vibration resistance

- SMT ignore reliable

- Having Less error of soldering point

- SMT has a high frequency that reduces electromagnetic and RF reduction

- It saves the cost of the device

Benefits of JLCPCB SMT

SMT PCBs are lightweight and provide a small circuit with better speeds. There are also additional benefits of employing this JLCPCB SMT service.

Production Speed and Efficiency

Because no holes in the electronic board are required, the manufacturing process is quick and efficient. This cuts down on machine setup time.

High signal Transmission

Not only are SMT manufactured components structurally small, but they also have a high safety density. When the PCB is pasted on both sides, the assembly density may reach 5.5-20 solder joints per square centimeter. Because of the short circuit and low latency, SMT manufactured PCBs may achieve fast signal transmission speeds. SMT-built PCBs, on the other hand, are more vibration and impact robust. This is critical for achieving ultra-high-speed electronic equipment functioning.

More Electronic Components

Additional components may be added on both sides of the electronics board. This enables you to make boards that are smaller and have more components.

Flexibility in project design

It allows both THT and SMT technologies to be used on the same board.

Simplify Production Process

The leads of components do not need to be bent, curved, or cut short when mounting on PCBs, which speeds up the process and improves manufacturing efficiency. The processing cost of the same functional circuit is cheaper than that of through-hole interpolation, which can cut overall manufacturing costs by 30% to 50%.

Cheap Cost

SMD components are less expensive than components with leads (THT). JLCPCB provides over 800,000 electronic components at a reasonable cost, allowing you to put together any product for the market. When dealing with SMT technology, however, there are a few things to keep in mind.

How SMT JLCPCB Reduces Cost?

JLCPCB offers cost-cutting changes. Their service provides clients with more pricing consistency and lower risk. The service includes an electronic component library with over 80,000 items. You may purchase for a reasonable cost and keep it safely and easily in a personal account. The following are some of the major benefits: the firm will keep your electrical components, and you will not be subject to market price swings. This procedure is achievable due to the presence of a specialized team. Customers’ needs and market price variations are studied, received, and analyzed by them. It helps you to ensure that your consumers have access to the most commonly used electronic components at lower pricing. This gives you access to the greatest components as well as huge revenues when it comes time to market your product.

How SMT JLCPCB Reduces Time?

Thousands of SMT components can be installed every hour, compared to less than a thousand with through-hole mounting. This, in turn, causes the product to be built as rapidly as possible, resulting in a shorter time to market.