Introduction

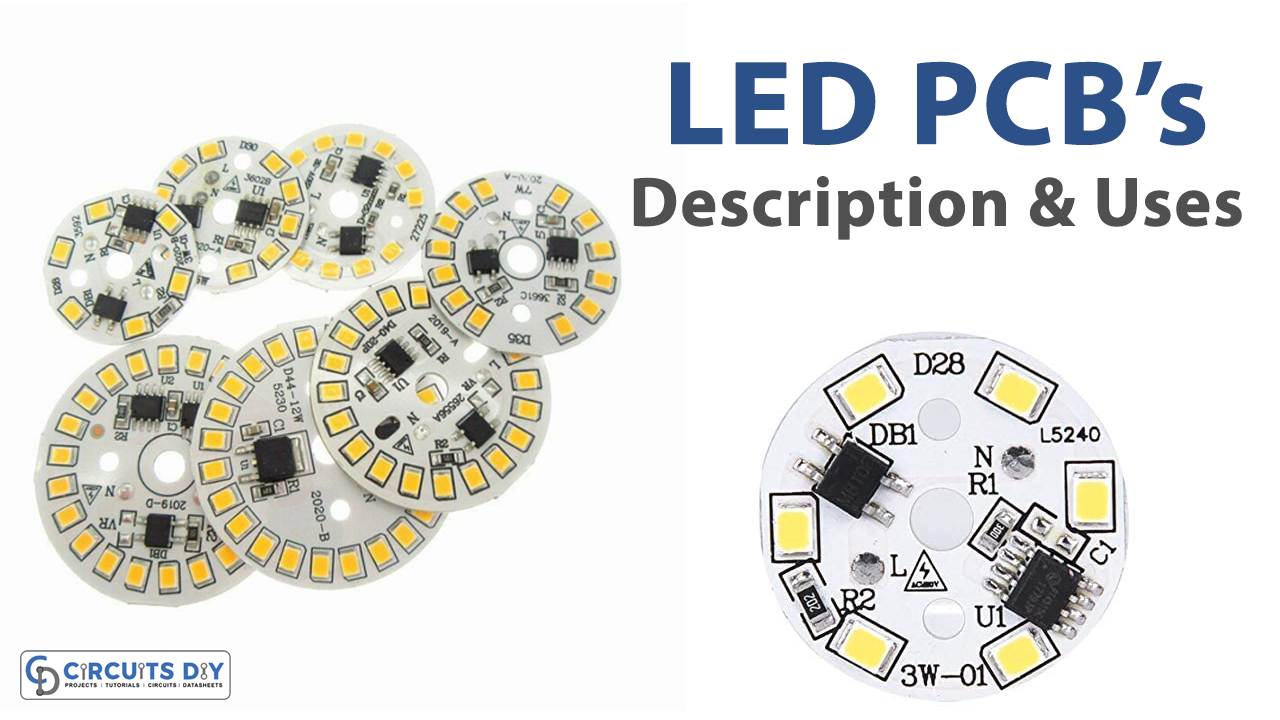

LED PCB, that is the light-emitted diode circuit boards are the boards that have LEDs soldered on them. LED. It creates the light as electrically connected. However, these PCBs generate high heat. For this purpose, metal core PCBs are used because they have an enriching aspect to dissipate heat. And, they incorporate the thin thermal conductive material that transfers the heat away from the board.

Usually, blue or white LEDs are used in embedded printed circuit boards. But a broader range of colors is available for these types of LEDs. Since it has so many applications and uses in electronic circuitry. Therefore, nowadays they are high in demand. Good quality manufacturing and high speed is the crucial factor for these PCBs.

Explanation About LED PCB

These LED PCBs do not use much power. This is highly used in electronic devices as an indicator. Also, it gets utilized in keypads, etc. There are some important points that designers need to think of while making circuits on LED PCBs. That is if the surface of the board is matte, there will be more diffusion of light. When the LEDs get mounted either on the surface mounted or through the hole. They must have to be mounted on the bottom level of the circuitry.

Single-point LEDs are incredibly versatile and are sufficient for maximum material surface texture.

Benefits of LED PCB

Since these PCBs have a large application in electronic devices. So, there must be some benefits to it. These benefits are:

- Use of no mercury: The LED lights on the board contain no mercury like other bulbs. So, they are environmentally friendly and can easily dispose of.

- Excellent Efficiency: They are more efficient unlike traditional bulbs that dissipate the extra amount of heat

- Less Power Consumption: They have a lower power consumption. And, have dimensional stability.

- Light Weight: The LED PCBs are very light in weight and have a low profile. Very compact

- Cheap in Prices: They are not very costly

- Better Resistant: They can resist dust and the moisture

Application and Uses

- Domestic Applications: Due to the above mention benefits. They are highly recommendable. Domestic applications widely use the LED PCBs

- Medical Applications: Due to its durability and high heat transfer abilities. Thus, it is used in medical applications. Like lightning tools, high-powered LED lights, medical scanning technology, etc

- Automotive Applications: In the automotive industry. Headlights, brake lights, and indicators of the vehicles use the LED PCB. Because they have a competitive price and high reliability rate

- Telecommunication Applications: Because of the greater heat transferability. Therefore, telecommunication devices widely use aluminum-based LED PCBs

- In Computer Applications: Computers are heat-sensitive devices. It needs to transfer the heat away from the machine. And, LED PCBs are good in heat transfer. Hence, used in computer applications.

Conclusion

The market is using LED PCBs. Because it has a large number of applications and usage. Since it has so many applications in electronic circuitry and devices. And that’s why we are assuming more innovation in these PCBs in the future.