Introduction

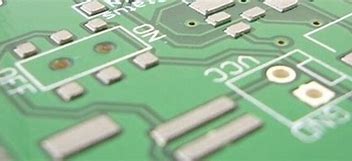

In the assembly process of the printed circuit boards, there is a paste that Is applied using the paste printer. This paste is regularly recognized as the solder paste. It’s a grey color form of solder having a viscous state, easy to apply on PCBs. Basically, the paste is the mixture of miniature balls and the flux, together they make a viscous paste. Practically, the paste is applied between the pads and the leads of the components mounted on the PCB. So, when the heat is applied to the PCB, the paste gets melted and makes the connection between those leads of electronic components and the pads.

Composition of Solder Paste

A solder paste regularly is the homogeneous mixture of alloy powder and solder flux. Thus, the most common alloy powder are Sn-Pb, Sn-Cu, Sn-Ag-Cu, etc. Hence, the most common solder flux includes a thixotropic agent, a solvent, resin, and an activator. Certainly, the solder flux is the fundamental material that prevents the soldering material from oxidation and cleans the metal surfaces. Moreover, the soldering flux has greater stability for the storage of solder paste. When applying on the PCB, remember to stir it before for the proper application of the uniform viscosity

Ratio of Alloy Powder and Flux

As we have discussed in the above heading that solder paste is composed of alloy powder and flux. However, they are not equally added to the solder paste. Since the ratio determines the viscosity of the paste, therefore it is necessary to prefer the commending ratio. A high proportion of powder means a greater viscosity of the paste. While a higher proportion of flux indicates a more moderate viscosity. Commonly, the paste is highly viscous. So, practically, the alloy powder is 75 to 90 percent in the solder paste.

Classification of Solder Paste

The paste has been classified based on flux and the basis of size. According to the flux, the division is basically based on cleaning, not cleaning, water cleaning, and controller cleaning. On the other hand, according to the size, it is classified into general spacing and narrow spacing. So the solder paste is classified into two types:

- By size

- By flux

(1) By Size

By size, the paste is divided into eight different sizes from type 1 to type 8. Consequently, the types are classified on different size parameters like average size, particle size, minimum size maximum size, etc. Thus, it estimates how the paste would be printed on the printed circuit boards. Moreover, it aids to reduce the oxidation of the surface and guarantees great joint formation.

(2) By Flux

According to the flux, the solder paste has three different types:

- Rosin Based: This sort of paste is made from a natural extract coming from the pine trees, rosin. The paste is cleaned after the soldering process. and, a solvent is used for cleaning purposes.

- Water Soluble: These kinds of paste are made from glycol and organic material. There is a wide range of solvents that are considered to clean this paste.

- No clean paste: This type of paste is made from different solid residues and resin. This type of flux saves the cleaning cost. However, it requires a high cleaning assembly environment.